Estamos comprometidos a brindar un servicio integral para productos de tubería de acero a clientes de todo el mundo.

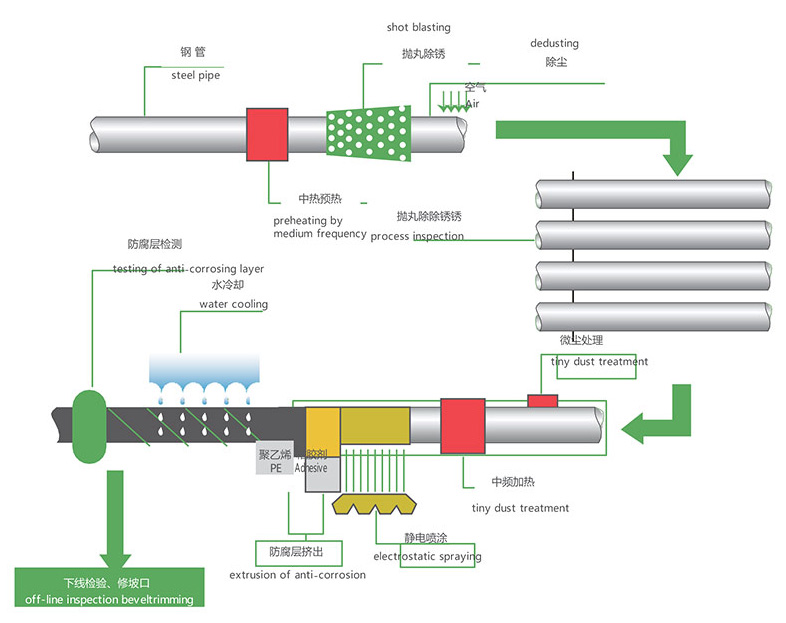

3LPP Pipe Coating i a three layer polypropylene coating technique that uses polypropylene as the coating material.There are three layers in this coating.The outer layer is the polypropylene in the 3lpp pipe coating and there is a middle layer made up of adhesives to bond the epoxy layer inside that is fusion bonded. This special structure protects the material from a number of conditions and materials.

The 3lpp pipeline coating is excellent in preventing the steel pipes from being in contact with corrosive chemicals and agents.Also the coating prevents the material to come into contact with any hard surfaced directly and prevents physical damage as wel.

The 3lpp coating pipe can come in different specifications such as DIN30678,CSAZ245.21-02,NF A49-711,ISO 9001:2008.The coating is also resistant to cathodic disbondment, meaning, thee coating is not affected by electric charge which can damage most other types of coatings. The 3lpp pipe can last longer and has higher performance compared to non - coated or other types of coatings. The application of this special coating is mostly in the oil fields which operate under high temperatures.The Three Layer Polypropylene Coated Pipe can be used in abrasion prone applications such as driling operations and in rocky surface applications.

A polypropylene(PP) coating in compliance with this standard shall be designated

Coating DIN 30678-PP

Service life of coatings

|

Operating temperature, |

Minimum

expected |

|

23 |

50 |

|

60 |

50 |

|

80 |

30 |

|

90 |

15 |

|

100 |

8 |

Minimum coating thickness

|

Norminal size |

Minimum coating thickness |

|

DN |

in mm |

|

Up to 100 |

1.8 |

|

125-250 |

2.0 |

|

300-500 |

2.2 |

|

600 or more |

2.5 |

1.ANSI*/AWWA C203—Coal-Tar Protective Coatings and Linings for Steel Water Pipe.

2.ANSI/AWWA C205—Cement-Mortar Protective Lining and Coating for Steel Water Pipe——4 In. (100 mm) and Larger——Shop Applied.

3.ANSI/AWWA C208—Dimensions for Fabricated Steel Water Pipe Fittings.

4.ANSI/AWWA C209—Cold-Applied Tape Coatings for Steel Water Pipe, Special Sections,Connections,and Fittings.

5.ANSI/AWWA C210—Liquid-Epoxy Coatings and Linings for Steel Water Pipe and Fittings.

6.ANSI/AWWA C213—Fusion-Bonded Epoxy Coatings and Linings for Steel Water Pipe and Fittings.

7.ANSI/AWWA C214—Tape Coatings for Steel Water Pipe.

8.ANSI/AWWA C215—Extruded Polyolefin Coatings for Steel Water Pipe.

9.ANSI/AWWA C216—Heat-Shrinkable Cross-Linked Polyolefin Coatings for Steel Water Pipe and Fittings.

10.ANSI/AWWA C217—Microcrystalline Wax and Petrolatum Tape Coating Systems for Steel Water Pipe and Fittings.

11.ANSI/AWWA C218—Liquid Coating Systems for Aboveground Steel Water Pipe and Fittings.

12.ANSI/AWWA C222—Polyurethane Coatings and Linings for Steel Water Pipe and Fittings.

13.ANSI/AWWA C224—Nylon-11-Based Polyamide Coatings and Linings for Steel Water Pipe Fittings.

14.ANSI/AWWA C225—Fused Polyolefin Coatings for Steel Water Pipe. ANSI/AWWA C229—Fusion-Bonded Polyethylene Coatings for Steel Water Pipe and Fittings.

15.ANSI/AWWA C602—Cement-Mortar Lining of Water Pipelines in Place———4 In.(100 mm) and Larger.

16.DIN3067—Polyethylene coatings of steel pipes and fittings —requirements and testing.

17.DIN30671—Thermoset plastic coatings for buried steel pipes

18.DIN3067—Coatings of corrosion protection tapes& heat shrinkable material for underground pipelines

19.DIN30678—Polypropylene coatings for steel pipes

20.DIN2614—Cement motar linings for ductile iron and steel pipes and fittings—application,requirements and testing

21.NF A49-710—Steel tubes.External coating with three polyethylene based coating.

22.NF A49-704—Polyethelene outer coating

23.AS1281—Cement mortar lining of steel pipes and fittings

24.NFA49-705—Steel tubes. External polyethylene coating. Application by powder sintering

25.AS1518—Extruded high density polyethylene protective coating for pipes

26.CAN/CSA-Z245.20—External Fusion Bond Epoxy Coating for Steel Pipe

27.BS EN10290-2002—Steel tubes and fittings for onshore and offshore pipelines. External liquid applied polyurethane and polyurethane-modified coatings

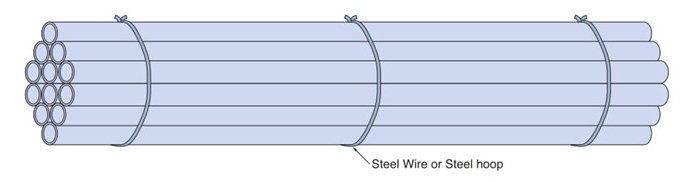

Bundled package

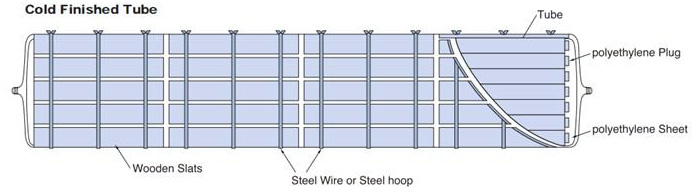

Wooden box package