Estamos comprometidos a brindar un servicio integral para productos de tubería de acero a clientes de todo el mundo.

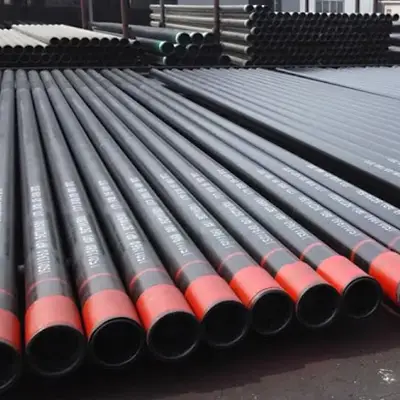

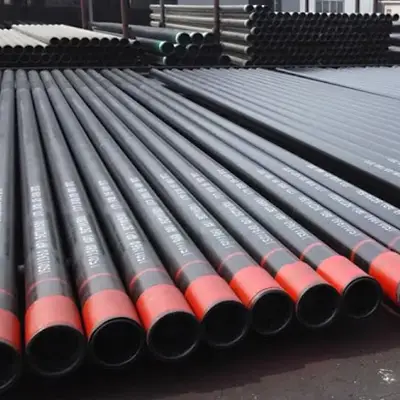

Casing is used for lining the complete borehole which has been dug into the ground to procure olil Similar to the drill ipe, the oil well casing pipe is also subjected to axial tension, therefore they are required to be made from high-quality strong steel material. OCTG casing is large diameter pipe which are held in place in the borehole using cement.

|

CASING AND TUBING |

API 5CT |

Casing:OD 4 1/2"- 20" (114.3mm-508mm) Tubing:OD 2 3/8" - 4 1/2" (60.3mm-114.30mm) WT: 0. 205"- 0.635" |

H-40, J55, K-55, N-80, C-75, L-80, C-90, T-95,P110,Q-125

|

|

Petroleum and natural gas industries - Steel pipes for use as casing or tubing for wells |

SY/T 6194 / BS EN ISO 11960/ NF M87-207 |

Casing:OD 4 1/2"- 20" (114.3mm-508mm) Tubing:OD 2 3/8" - 4 1/2" (60.3mm-114.30mm) WT: 0. 205"- 0.635" |

H-40, J55, K-55, N-80,N80Q,C-75, L-80, C-90, T-95,P110,Q-125 |

|

Oil Tubing |

Range 1 |

Range 2 |

Range 3 |

|

6.10~7.32 |

8.53~9.75 |

11.58~12.80 |

|

Label |

D Outside diameter mm |

Wall thickness mm |

C type of end-finish |

|||||||||

|

1 |

2 |

|||||||||||

|

NU T&C |

EU T&C |

IJ |

H40 |

J55 |

L80 |

N80 |

C90 |

T95 |

P110 |

|||

|

1.9 |

2.75 |

2.9 |

4 |

48.26 |

3.68 |

PNUI |

PNUI |

PNUI |

PNUI |

PNUI |

PNUI |

|

|

3.65 |

3.73 |

2.76 |

48.26 |

5.08 |

PU |

PU |

PU |

PU |

PU |

PU |

PU |

|

|

4.42 |

- |

- |

48.26 |

6.35 |

- |

- |

P |

- |

P |

P |

- |

|

|

2 3/8 |

4 |

- |

- |

60.32 |

4.24 |

PU |

PN |

PN |

PN |

PN |

PN |

- |

|

4.6 |

4.7 |

- |

60.32 |

4.83 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

5.8 |

5.95 |

- |

60.32 |

6.45 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

6.6 |

- |

- |

60.32 |

7.49 |

- |

- |

P |

- |

P |

P |

- |

|

|

7.35 |

7.45 |

- |

60.32 |

8.53 |

- |

- |

PU |

- |

PU |

PU |

- |

|

|

2 7/8 |

6.4 |

6.5 |

- |

73.02 |

5.51 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

7.8 |

7.9 |

- |

73.02 |

7.01 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

8.6 |

8.7 |

- |

73.02 |

7.82 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

9.35 |

9.45 |

- |

73.02 |

8.64 |

- |

- |

PU |

- |

PU |

PU |

- |

|

|

10.5 |

- |

- |

73.02 |

9.96 |

- |

- |

P |

- |

P |

P |

- |

|

|

3 1/2 |

7.7 |

- |

- |

88.9 |

5.49 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

9.2 |

9.3 |

- |

88.9 |

6.45 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

10.2 |

- |

- |

88.9 |

7.34 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

|

12.7 |

12.95 |

- |

88.9 |

9.52 |

- |

- |

PNU |

- |

PNU |

PNU |

PNU |

|

|

14.3 |

- |

- |

88.9 |

10.92 |

- |

- |

P |

- |

P |

P |

- |

|

|

15.5 |

- |

- |

88.9 |

12.09 |

- |

- |

P |

- |

P |

P |

- |

|

|

4 |

9.5 |

- |

- |

101.6 |

5.74 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

10.7 |

11 |

- |

101.6 |

6.65 |

PU |

PU |

PU |

PU |

PU |

PU |

- |

|

|

13.2 |

- |

- |

101.6 |

8.38 |

- |

- |

P |

- |

P |

P |

- |

|

|

16.1 |

- |

- |

101.6 |

10.54 |

- |

- |

P |

- |

P |

P |

- |

|

|

4 1/2 |

12.6 |

12.75 |

- |

114.3 |

6.88 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

- |

|

15.2 |

- |

- |

114.3 |

8.56 |

- |

- |

P |

- |

P |

P |

- |

|

|

Pipe Types |

Pipe Size (mm) |

Tolerances |

|

|

Hot Rolled |

OD |

≤159 |

±1.0% |

|

>159 |

±1.20% |

||

|

WT |

≤20 |

±12.5% |

|

|

>20 |

±10.0% |

||

|

Cold Drawn |

OD |

≤30 |

±0.20mm |

|

30-50 |

±0.30mm |

||

|

>50 |

±0.8% |

||

|

WT |

≤3 |

+12% -10% |

|

|

>3 |

±10% |

||

API Spec 5CT – Specification 5CT/ISO 11960, Specification for Casing and Tubing, Eighth Edition, Petroleum and natural gas industries-Steel pipes for use as casing or tubing for wells

Mechanical Properties:

|

Group |

Grade |

Type |

Total elongation under load % |

Yield Strength M pa |

Tensile strength min Mpa |

Hardness |

||

|

min |

max |

HRC |

HBW |

|||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

2 |

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

|

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

3 |

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

C90 |

|

0.5 |

621 |

689 |

689 |

25.4 |

255 |

|

|

C95 |

- |

0.5 |

655 |

724 |

724 |

- |

- |

|

|

T95 |

|

0.5 |

655 |

724 |

724 |

25.4 |

255 |

|

|

P110 |

- |

0.6 |

758 |

862 |

862 |

- |

- |

|

|

4 |

Q125 |

All |

0.65 |

862 |

931 |

931 |

- |

- |

Chemical Composition

|

Standard |

Grade |

Composition(%) |

||||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

AIs |

||

|

API SPEC 5CT |

J55K55 |

0.34~0.39 |

0.20~ |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

|

|

≤0.020 |

|

(37Mn5) |

||||||||||||

|

N80 |

0.34~0.38 |

0.20~ |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

|

|

|

0.11 |

≤0.020 |

|

|

(36 Mn2V) |

||||||||||||

|

L80(13Cr) |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~ |

≤0.20 |

≤0.20 |

|

|

≤0.020 |

|

|

P110 |

0.26~0.35 |

0.17~ |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~ |

≤0.20 |

≤0.20 |

0.15 |

≤0.08 |

≤0.020 |

|

|

|

||||||||||||

Round Pipe → pipe inspection → NDT inspection MPI → End Threading → Thread Inspection → Coupling Threading lnspection → NDT inspection MPI ( coupling) → Phosphating (for coupling) → Coupling power Make up → Hydrostatic test → Drift test → Doping and Protectors Application → Coating → Measurement of Length and Weight → Colour Identification → Marking → Packing → Warehousing

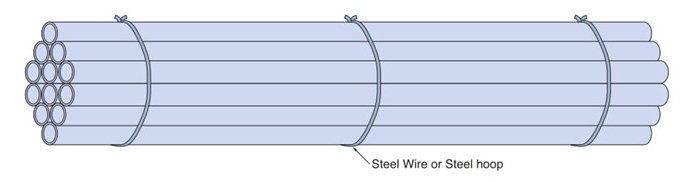

Bundled package

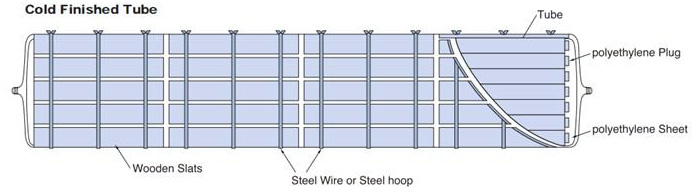

Wooden box package