We are committed to providing one-stop service for steel pipe products to customers around the world.

Tubing is used for a variety of applications, including fluid and gas transportation, structural support, electrical and electronic wiring, medical procedures, and more.

|

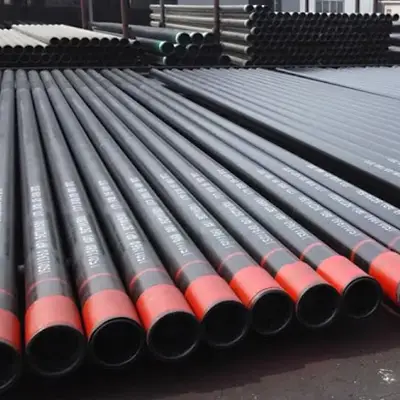

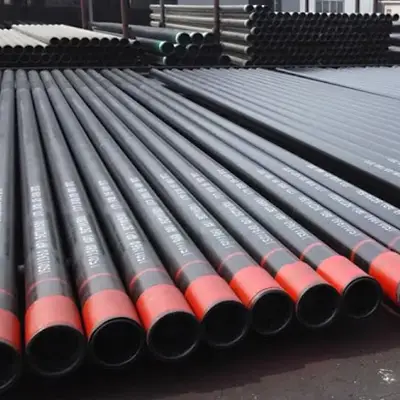

CASING AND TUBING |

API 5CT |

Casing:OD 4 1/2"- 20" (114.3mm-508mm) Tubing:OD 2 3/8" - 4 1/2" (60.3mm-114.30mm) WT: 0. 205"- 0.635" |

H-40, J55, K-55, N-80, C-75, L-80, C-90, T-95,P110,Q-125

|

|

Petroleum and natural gas industries - Steel pipes for use as casing or tubing for wells |

SY/T 6194 / BS EN ISO 11960/ NF M87-207 |

Casing:OD 4 1/2"- 20" (114.3mm-508mm) Tubing:OD 2 3/8" - 4 1/2" (60.3mm-114.30mm) WT: 0. 205"- 0.635" |

H-40, J55, K-55, N-80,N80Q,C-75, L-80, C-90, T-95,P110,Q-125 |

|

il Tubing |

Range 1 |

Range 2 |

Range 3 |

|

6.10~7.32 |

8.53~9.75 |

11.58~12.80 |

|

Label |

D Outside diameter mm |

Wall thickness mm |

C type of end-finish |

|||||||||

|

1 |

2 |

|||||||||||

|

NU T&C |

EU T&C |

IJ |

H40 |

J55 |

L80 |

N80 |

C90 |

T95 |

P110 |

|||

|

1.9 |

2.75 |

2.9 |

4 |

48.26 |

3.68 |

PNUI |

PNUI |

PNUI |

PNUI |

PNUI |

PNUI |

|

|

3.65 |

3.73 |

2.76 |

48.26 |

5.08 |

PU |

PU |

PU |

PU |

PU |

PU |

PU |

|

|

4.42 |

- |

- |

48.26 |

6.35 |

- |

- |

P |

- |

P |

P |

- |

|

|

2 3/8 |

4 |

- |

- |

60.32 |

4.24 |

PU |

PN |

PN |

PN |

PN |

PN |

- |

|

4.6 |

4.7 |

- |

60.32 |

4.83 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

5.8 |

5.95 |

- |

60.32 |

6.45 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

6.6 |

- |

- |

60.32 |

7.49 |

- |

- |

P |

- |

P |

P |

- |

|

|

7.35 |

7.45 |

- |

60.32 |

8.53 |

- |

- |

PU |

- |

PU |

PU |

- |

|

|

2 7/8 |

6.4 |

6.5 |

- |

73.02 |

5.51 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

7.8 |

7.9 |

- |

73.02 |

7.01 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

8.6 |

8.7 |

- |

73.02 |

7.82 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

9.35 |

9.45 |

- |

73.02 |

8.64 |

- |

- |

PU |

- |

PU |

PU |

- |

|

|

10.5 |

- |

- |

73.02 |

9.96 |

- |

- |

P |

- |

P |

P |

- |

|

|

3 1/2 |

7.7 |

- |

- |

88.9 |

5.49 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

9.2 |

9.3 |

- |

88.9 |

6.45 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

10.2 |

- |

- |

88.9 |

7.34 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

|

12.7 |

12.95 |

- |

88.9 |

9.52 |

- |

- |

PNU |

- |

PNU |

PNU |

PNU |

|

|

14.3 |

- |

- |

88.9 |

10.92 |

- |

- |

P |

- |

P |

P |

- |

|

|

15.5 |

- |

- |

88.9 |

12.09 |

- |

- |

P |

- |

P |

P |

- |

|

|

4 |

9.5 |

- |

- |

101.6 |

5.74 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

10.7 |

11 |

- |

101.6 |

6.65 |

PU |

PU |

PU |

PU |

PU |

PU |

- |

|

|

13.2 |

- |

- |

101.6 |

8.38 |

- |

- |

P |

- |

P |

P |

- |

|

|

16.1 |

- |

- |

101.6 |

10.54 |

- |

- |

P |

- |

P |

P |

- |

|

|

4 1/2 |

12.6 |

12.75 |

- |

114.3 |

6.88 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

- |

|

15.2 |

- |

- |

114.3 |

8.56 |

- |

- |

P |

- |

P |

P |

- |

|

Note: P—plain-end;N—non-upset, with threaded and coupled;U—external-upset, with threaded and coupled;I—whole joint

|

Pipe Types |

Pipe Size (mm) |

Tolerances |

|

|

Hot Rolled |

OD |

≤159 |

±1.0% |

|

>159 |

±1.20% |

||

|

WT |

≤20 |

±12.5% |

|

|

>20 |

±10.0% |

||

|

Cold Drawn |

OD |

≤30 |

±0.20mm |

|

30-50 |

±0.30mm |

||

|

>50 |

±0.8% |

||

|

WT |

≤3 |

+12% -10% |

|

|

>3 |

±10% |

||

|

Oil Tubing |

Range 1 |

Range 2 |

Range 3 |

|

6.10~7.32 |

8.53~9.75 |

11.58~12.80 |

|

Label |

D Outside diameter mm |

Wall thickness mm |

C type of end-finish |

|||||||||

|

1 |

2 |

|||||||||||

|

NU T&C |

EU T&C |

IJ |

H40 |

J55 |

L80 |

N80 |

C90 |

T95 |

P110 |

|||

|

1.9 |

2.75 |

2.9 |

4 |

48.26 |

3.68 |

PNUI |

PNUI |

PNUI |

PNUI |

PNUI |

PNUI |

|

|

3.65 |

3.73 |

2.76 |

48.26 |

5.08 |

PU |

PU |

PU |

PU |

PU |

PU |

PU |

|

|

4.42 |

- |

- |

48.26 |

6.35 |

- |

- |

P |

- |

P |

P |

- |

|

|

2 3/8 |

4 |

- |

- |

60.32 |

4.24 |

PU |

PN |

PN |

PN |

PN |

PN |

- |

|

4.6 |

4.7 |

- |

60.32 |

4.83 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

5.8 |

5.95 |

- |

60.32 |

6.45 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

6.6 |

- |

- |

60.32 |

7.49 |

- |

- |

P |

- |

P |

P |

- |

|

|

7.35 |

7.45 |

- |

60.32 |

8.53 |

- |

- |

PU |

- |

PU |

PU |

- |

|

|

2 7/8 |

6.4 |

6.5 |

- |

73.02 |

5.51 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

7.8 |

7.9 |

- |

73.02 |

7.01 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

8.6 |

8.7 |

- |

73.02 |

7.82 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

9.35 |

9.45 |

- |

73.02 |

8.64 |

- |

- |

PU |

- |

PU |

PU |

- |

|

|

10.5 |

- |

- |

73.02 |

9.96 |

- |

- |

P |

- |

P |

P |

- |

|

|

3 1/2 |

7.7 |

- |

- |

88.9 |

5.49 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

9.2 |

9.3 |

- |

88.9 |

6.45 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

10.2 |

- |

- |

88.9 |

7.34 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

|

12.7 |

12.95 |

- |

88.9 |

9.52 |

- |

- |

PNU |

- |

PNU |

PNU |

PNU |

|

|

14.3 |

- |

- |

88.9 |

10.92 |

- |

- |

P |

- |

P |

P |

- |

|

|

15.5 |

- |

- |

88.9 |

12.09 |

- |

- |

P |

- |

P |

P |

- |

|

|

4 |

9.5 |

- |

- |

101.6 |

5.74 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

10.7 |

11 |

- |

101.6 |

6.65 |

PU |

PU |

PU |

PU |

PU |

PU |

- |

|

|

13.2 |

- |

- |

101.6 |

8.38 |

- |

- |

P |

- |

P |

P |

- |

|

|

16.1 |

- |

- |

101.6 |

10.54 |

- |

- |

P |

- |

P |

P |

- |

|

|

4 1/2 |

12.6 |

12.75 |

- |

114.3 |

6.88 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

- |

|

15.2 |

- |

- |

114.3 |

8.56 |

- |

- |

P |

- |

P |

P |

- |

|

|

Pipe Types |

Pipe Size (mm) |

Tolerances |

|

|

Hot Rolled |

OD |

≤159 |

±1.0% |

|

>159 |

±1.20% |

||

|

WT |

≤20 |

±12.5% |

|

|

>20 |

±10.0% |

||

|

Cold Drawn |

OD |

≤30 |

±0.20mm |

|

30-50 |

±0.30mm |

||

|

>50 |

±0.8% |

||

|

WT |

≤3 |

+12% -10% |

|

|

>3 |

±10% |

||

API Spec 5CT – Specification 5CT/ISO 11960, Specification for Casing and Tubing, Eighth Edition, Petroleum and natural gas industries-Steel pipes for use as casing or tubing for wells

Mechanical Properties:

|

Group |

Grade |

Type |

Total elongation under load % |

Yield Strength M pa |

Tensile strength min Mpa |

Hardness |

||

|

min |

max |

HRC |

HBW |

|||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

2 |

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

|

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

3 |

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

C90 |

|

0.5 |

621 |

689 |

689 |

25.4 |

255 |

|

|

C95 |

- |

0.5 |

655 |

724 |

724 |

- |

- |

|

|

T95 |

|

0.5 |

655 |

724 |

724 |

25.4 |

255 |

|

|

P110 |

- |

0.6 |

758 |

862 |

862 |

- |

- |

|

|

4 |

Q125 |

All |

0.65 |

862 |

931 |

931 |

- |

- |

Chemical Composition

|

Standard |

Grade |

Composition(%) |

||||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

AIs |

||

|

API SPEC 5CT |

J55K55 |

0.34~0.39 |

0.20~ |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

|

|

≤0.020 |

|

(37Mn5) |

||||||||||||

|

N80 |

0.34~0.38 |

0.20~ |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

|

|

|

0.11 |

≤0.020 |

|

|

(36 Mn2V) |

||||||||||||

|

L80(13Cr) |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~ |

≤0.20 |

≤0.20 |

|

|

≤0.020 |

|

|

P110 |

0.26~0.35 |

0.17~ |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~ |

≤0.20 |

≤0.20 |

0.15 |

≤0.08 |

≤0.020 |

|

|

|

||||||||||||

Round Pipe → pipe inspection → NDT inspection MPI → End Threading → Thread Inspection → Coupling Threading lnspection → NDT inspection MPI ( coupling) → Phosphating (for coupling) → Coupling power Make up → Hydrostatic test → Drift test → Doping and Protectors Application → Coating → Measurement of Length and Weight → Colour Identification → Marking → Packing → Warehousing

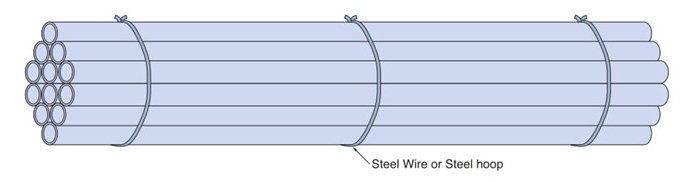

Bundled package

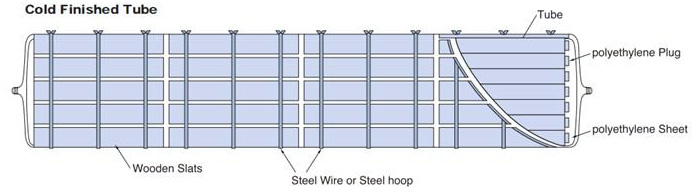

Wooden box package