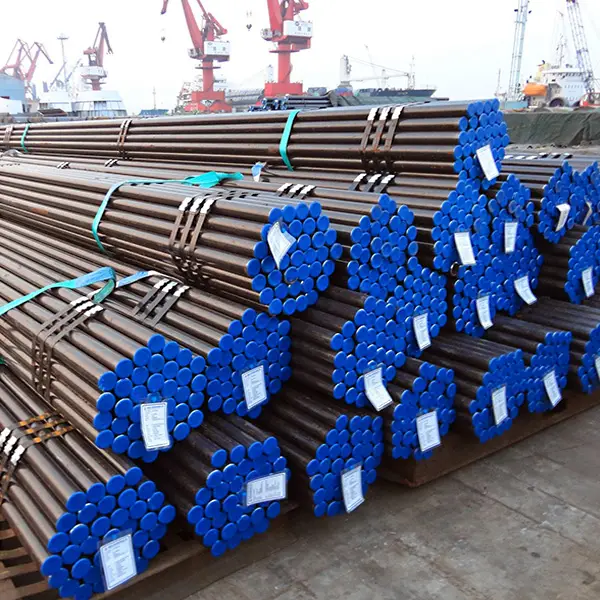

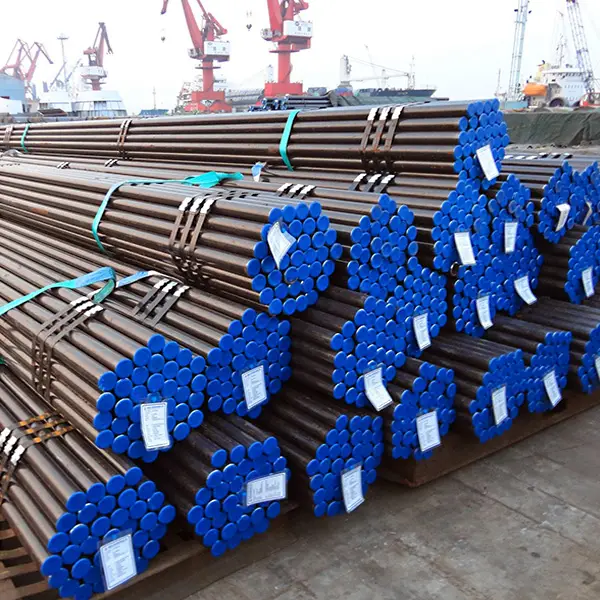

We are committed to providing one-stop service for steel pipe products to customers around the world.

ASTM A210/A210M Seamless bolier tube is a Seamless medium carbon steel Boiler Tube used in super heater, heat exchangers, condensers, marine application, refineries, paper pulping, petrochemical applications, pressure vessels, and general engineering applications. It is also used in coal, thermal and oil power generation plants. SA210A1 steel can be purchased HF (hot finished) or CD (cold drawn) and shall be killed. SA213T2 has a maximum hardness of 85 HRB (Rockwell B) and is a P1 Material.

Wall Thickness & Tolerance OF ASTM A210/A210M Seamless bolier tube

|

|

Outside Diameter, mm |

Tolerance, % |

|

Hot rolled |

OD≤101.6, WT≤2.4 |

+40/-0 |

|

OD≤101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD≤101.6, 3.8<WT≤4.6 |

+33/-0 |

|

|

OD≤101.6, WT>4.6 |

+28/-0 |

|

|

OD>101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD>101.6, 3.8<WT≤4.6 |

+33/-0 |

|

|

OD>101.6, WT>4.6 |

+28/-0 |

|

|

|

Outside Diameter, mm |

Tolerance, % |

|

Cold Drawn |

OD≤38.1 |

+20/0 |

|

OD>38.1 |

+22/0 |

Outer Diameter & Tolerance OF ASTM A210/A210M Seamless bolier tube

|

|

Outside Diameter, mm |

Tolerance, mm |

|

Hot rolled |

OD≤101.6 |

+0.4/-0.8 |

|

101.6<OD≤177.8 |

+0.4/-1.2 |

|

|

|

Outside Diameter, mm |

Tolerance, % |

|

Cold Drawn |

OD<25.4 |

±0.10 |

|

25.4≤OD≤38.1 |

±0.15 |

|

|

38.1<OD<50.8 |

±0.20 |

|

|

50.8≤OD<63.5 |

±0.25 |

|

|

63.5≤OD<76.2 |

±0.30 |

|

|

76.2≤OD≤101.6 |

±0.38 |

|

|

101.6<OD≤177.8 |

+0.38/-0.64 |

Chemical Composition OF ASTM A210/A210M Seamless bolier tube

|

Grade |

Carbon |

Manganese |

Phosphorus |

Sulfur |

Silicon |

|

ASTM A210 Gr A1 |

0.27% Max |

0.93% Max |

0.035% Max |

0.035% Max |

0.10% min |

|

ASTM A210 Gr C |

0.35% Max |

0.29% - 1.06% |

0.035% Max |

0.035% Max |

0.10% Min |

Mechanical Properties OF ASTM A210/A210M Seamless bolier tube

|

Grade |

P # |

Tensile Strength |

Yield |

Max Hardness |

Check Inventoryon |

|

|

ASTM A210 Gr A1 |

P 1 |

ksi: 60 MPa: 415 |

ksi: 37 MPa: 255 |

79 HRB (Rockwell B) |

143 HB (Brinell) |

A210 Gr A Inventory |

|

ASTM A210 Gr C |

P 1 |

ksi: 70 MPa: 485 |

ksi: 40 MPa: 275 |

89 HRB (Rockwell B) |

179 HB (Brinell) |

A210 Gr A Inventory |

Test requirement:tension test, flattening test, flaring test, hardness test, hydrostatic or nondestructive electric test,etc.

Additional Fabrication Service:Bending and othering fabrication according to customer requirement.

Wall Thickness & Tolerance OF ASTM A210/A210M Seamless bolier tube

|

|

Outside Diameter, mm |

Tolerance, % |

|

Hot rolled |

OD≤101.6, WT≤2.4 |

+40/-0 |

|

OD≤101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD≤101.6, 3.8<WT≤4.6 |

+33/-0 |

|

|

OD≤101.6, WT>4.6 |

+28/-0 |

|

|

OD>101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD>101.6, 3.8<WT≤4.6 |

+33/-0 |

|

|

OD>101.6, WT>4.6 |

+28/-0 |

|

|

|

Outside Diameter, mm |

Tolerance, % |

|

Cold Drawn |

OD≤38.1 |

+20/0 |

|

OD>38.1 |

+22/0 |

Outer Diameter & Tolerance OF ASTM A210/A210M Seamless bolier tube

|

|

Outside Diameter, mm |

Tolerance, mm |

|

Hot rolled |

OD≤101.6 |

+0.4/-0.8 |

|

101.6<OD≤177.8 |

+0.4/-1.2 |

|

|

|

Outside Diameter, mm |

Tolerance, % |

|

Cold Drawn |

OD<25.4 |

±0.10 |

|

25.4≤OD≤38.1 |

±0.15 |

|

|

38.1<OD<50.8 |

±0.20 |

|

|

50.8≤OD<63.5 |

±0.25 |

|

|

63.5≤OD<76.2 |

±0.30 |

|

|

76.2≤OD≤101.6 |

±0.38 |

|

|

101.6<OD≤177.8 |

+0.38/-0.64 |

Chemical Composition OF ASTM A210/A210M Seamless bolier tube

|

Grade |

Carbon |

Manganese |

Phosphorus |

Sulfur |

Silicon |

|

ASTM A210 Gr A1 |

0.27% Max |

0.93% Max |

0.035% Max |

0.035% Max |

0.10% min |

|

ASTM A210 Gr C |

0.35% Max |

0.29% - 1.06% |

0.035% Max |

0.035% Max |

0.10% Min |

Mechanical Properties OF ASTM A210/A210M Seamless bolier tube

|

Grade |

P # |

Tensile Strength |

Yield |

Max Hardness |

Check Inventoryon |

|

|

ASTM A210 Gr A1 |

P 1 |

ksi: 60 MPa: 415 |

ksi: 37 MPa: 255 |

79 HRB (Rockwell B) |

143 HB (Brinell) |

A210 Gr A Inventory |

|

ASTM A210 Gr C |

P 1 |

ksi: 70 MPa: 485 |

ksi: 40 MPa: 275 |

89 HRB (Rockwell B) |

179 HB (Brinell) |

A210 Gr A Inventory |

Test requirement:tension test, flattening test, flaring test, hardness test, hydrostatic or nondestructive electric test,etc.

Additional Fabrication Service:Bending and othering fabrication according to customer requirement.

Round Pipe Billet → Heating → Punching → Pipe Head Treatment → Annealing →Acid Pickling →

Coating Oil (Copper Plating) → Multi-pass Cold Drawing or Cold Rolling → Pipe Billet → Heat Treatment → Straightening → Hydrostatic Test or Inspection → Marking → Warehousing