We are committed to providing one-stop service for steel pipe products to customers around the world.

Carbon steel pipes are divided into hot rolled and cold rolled (pulled) steel pipes.

Hot rolled carbon steel pipeis divided into ordinary steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, geological steel pipe and other steel pipe, etc.

Cold rolled (dialed) carbon steel pipeis divided into ordinary steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, other steel pipe, but also includes carbon thin-walled steel pipe, alloy thin-walled steel pipe

Carbon Steel Seamless Pipes– it contains more carbon and iron in its composition. Depending on the grade, trace amounts of silicon, manganese, and copper are permitted in varying quantities. Therefore, the Carbon Steel Seamless Pipe material is stronger and is extremely resistant to stress. In heavy-duty facilities, these features make the pipes applicable.

Carbon Steel Welded Pipes– are used in high-pressure conditions. In a range of industries, such as the transport of water and waste, the oil and gas industries, high-pressure applications, and chemical manufacturing, carbon steel pipes are commonly used.

Carbon Steel ERW Pipes– have various features like Lightweight, Corrosion resistance, structured appropriately, Precision engineered, intricate detailing, Economical, and more. These ERW pipes are used in Ship Building, Automobile, Boilers & Pressure Vessels, Railways, Oil & Petro Chemicals, Coal & Mining, Transmission Towers, and General & Heavy Engineering.

Carbon Steel LSAW Pipes– has some fine features such as easy installation, seamless finish, Rustproof, and more. As these LSAW pipes are expensive, they are not widely used in lower value non-energy applications such as water pipelines.

|

Seamless sizes |

Welded sizes |

Application |

|

Out diameter: 1/4"-36" |

Out diameter: 21.3mm-3620mm |

API 5L, API 5CT, ASTM A53, ASTM A106, ASTM A179, ASTM A192, ASTM A252, ASTM A333, ASTM A335, ASTM A672 Water underground

Sewage treatment |

|

Wall thickness:1.25mm-50mm |

Wall thickness:1.65-mm-65mm |

|

|

Length:3m-12m |

Length:3m-12m |

API 5L

for use in conveying gas, water, and oil in the natural gas and oil industries, and covers seamless and welded steel line pipe.

API 5CT

for casing and tubing

ASTM A53

for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

ASTM A106

for Seamless Carbon Steel Pipe for High-Temperature Service

ASTM A179

for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes

ASTM A192

for Seamless Carbon Steel Boiler Tubes for High-Pressure Service

ASTM A213

for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM A252

for Welded and Seamless Steel Pipe Piles

ASTM A333

for Seamless and Welded Steel Pipe for Low-Temperature Service and Other Applications with Required Notch Toughness

ASTM A672

for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures

ASTM A335

for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

DIN 17175

seamless steel pipes are used in boiler installations, high-pressure pipelines and tank construction and special machinery for both high temperature and high-pressure devices.

DIN 1629

specifies the Seamless Circular Tubes of Non Alloys Steels with Special Quality Requirements.

DIN 2391

for Cold Drawn High Precision Seamless Tube

DIN 2458

Welded Steel Pipes in Unalloyed and Low Alloy Steels for Supply Purposes

EN 10210

Seamless steel tubes for pressure purposes

BS 3059

Steel boiler and superheater tubes

JIS G3454

Carbon steel pipes for pressure service

Chemical Properties

specification

Grade

Chemical Composition [%]

C

Mn

P

S

Si

Cr

Mo

Cu

Ni

V

Min

Max.

Min

Max.

Max.

Max.

Min.

Max

Min.

Max

Min.

Max

Max

Max

Max

HYDROCARBON PROCESS INDUSTRY/STRUCTURAL/PRESSURE VESSEL TUBES

ASTM

A-53

A

-

-

0.25

0.30

-

-

0.95

1.20

0.050

0.050

0.045

0.045

-

-

-

-

-

-

0.40

0.40

-

-

0.15

0.15

0.40 for S

0.40 for S

0.40

0.40

0.08

0.08

ASTM

A-106

A

c

-

-

-

0.25

0.30

0.35

0.27

0.29

0.29

0.93

1.06

1.06

0.035

0.035

0.035

0.035

0.035

0.035

0.10

0.10

0.10

-

-

-

-

-

-

0.40

0.40

0.40

-

-

-

0.15

0.15

0.15

0.40

0.40

0.40

0.40

-

0.08

0.08

0.08

ASTM

A333 & A 334

1

-

0.30

0.30

0.40

0.29

1.06

1.06

0.025

0.025

0.025

0.025

-

0.10

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

SEAMLESS COLD DRAWN PRECISION STEEL TUBES FOR MECHANICAL APPLICATIONS/HYDRAULIC/PNEUMATIC POWER SYSTEMS

EN 10305-1/

EN10305-4

E 235

E 355

0.17

0.22

1.2

1.6

0.025

0.025

0.025

0.025

0.35

0.55

0.02

0.02

EN 10216-1

P195 TR1

0.13

0.16

0.7

1.2

0.025

0.025

0.02

0.02

0.35

0.35

0.3

0.3

0.08

0.08

0.3

0.3

0.3

0.3

EN 10216-2

P235 GH

0.16

1.2

0.025

0.02

0.35

0.3

0.08

0.3

0.3

0.02

DIN 2391

St - 45

-

0.17

0.21

0.22

0.40

0.40

-

-

-

1.60

0.025

0.025

0.025

0.025

0.025

0.025

-

-

-

0.35

0.35

0.55

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

ASTM

A-519

SAE 1010

SAE 1040

SAE 1518

SAE 1541

SAE 4130

0.08

0.15

0.22

0.32

0.37

0.15

0.36

0.28

0.13 0.20

0.28

0.38

0.44

0.21

0.44

0.33

0.30

0.60

0.60

0.60

0.60

1.10

1.35

0.40

0.60

0.90

0.90

0.90

0.90

1.40

1.65

0.60

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.050

0.050

0.050

0.050

0.050

0.050

0.050

0.040

-

-

-

-

-

-

-

0.15

-

-

-

-

-

-

-

0.35

-

-

-

-

-

-

-

0.80

-

-

-

-

-

-

-

1.10

-

-

-

-

-

-

-

0.15

-

-

-

-

-

-

-

0.25

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

BOILER/HEAT EXCHANGER/SUPERHEATER & CONDENSER TUBES

ASTM A179

-

0.06

0.18

0.27

0.63

0.035

0.035

-

-

-

-

-

-

-

-

-

ASTM A192

0.06

0.18

0.27

0.63

0.035

0.035

-

0.25

-

-

-

-

-

-

-

ASTM

A 210

A-1

-

0.27

0.35

-

0.29

0.93

1.06

0.035

0.035

0.035

0.035

0.10

0.10

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

ASTM

A 213

T-11

T-22

0.05

0.05

0.05

0.15

0.15

0.15

0.30

0.30

0.30

0.60

0.61

0.60

0.025

0.025

0.025

0.025

0.025

0.025

0.50

-

-

1.00

0.50

0.50

1.00

0.80

1.90

1.50

1.25

2.60

0.44

0.44

0.87

0.65

0.65

1.13

-

-

-

-

-

-

-

-

-

ASTM

P-11

P-22

0.05

0.05

0.05

0.15

0.15

0.15

0.30

0.30

0.30

0.60

0.61

0.60

0.025

0.025

0.025

0.025

0.025

0.025

0.50

-

-

1.00

0.50

0.50

1.00

0.80

1.90

1.50

1.25

2.60

0.44

0.44

0.87

0.65

0.65

1.13

-

-

-

-

-

-

-

-

-

BS 3059 Pt I

320

-

0.16

0.30

0.70

0.040

0.040

0.10

0.35

-

-

-

-

-

-

-

BS 3059 Pt II

622-490

0.08

0.15

0.40

0.70

0.030

0.030

-

0.50

2.00

2.50

0.90

1.20

-

-

-

DIN 1629

St- 37.0

St - 52

-

-

0.17

0.22

-

-

-

-

0.040

0.040

0.040

0.035

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

DIN 17175

St - 35.8

St - 45.8

-

-

0.17

0.21

0.40

0.40

0.80

1.20

0.040

0.040

0.040

0.040

0.10

0.10

0.35

0.35

-

-

-

-

-

-

-

-

-

-

-

-

-

-

RAILWAYS

IS:1239 Pt I

-

-

-

-

-

0.050

0.050

-

-

-

-

-

-

-

-

-

IS:1161

YST-210

YST-240

YST-310

-

-

-

0.12

0.16

0.25

-

-

-

0.60

1.20

1.30

0.040

0.040

0.040

0.040

0.040

0.040

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Mechanical Properties

Grade A

Grade B

Grade C

Tensile strength, min, psi (MPa)

48,000 (330)

60000 (415)

70,000 (485)

Yield strength, min, psi (MPa)

30,000 (205)

35,000 (240)

40,000 (275)

B

B

6

-

P235 TR1

St - 45

St - 52

-

-

SAE 1018

SAE 1026

SAE 1035

C

-

T-12

A335

P-12

|

NOMINAL PIPE SIZE |

OD (mm) |

NOMINAL WALL THICKNESS |

|||||||||||||

|

DN |

NB(inch) |

ASME |

SCH10 |

SCH20 |

SCH30 |

STD |

SCH40 |

SCH60 |

XS |

SCH80 |

SCH100 |

SCH120 |

SCH140 |

SCH160 |

XXS |

|

15 |

1/2" |

21.3 |

2.11 |

|

2.41 |

2.77 |

2.77 |

|

3.73 |

3.73 |

|

|

|

4.78 |

7.47 |

|

20 |

3/4" |

26.7 |

2.11 |

|

2.41 |

2.87 |

2.87 |

|

3.91 |

3.91 |

|

|

|

5.56 |

7.82 |

|

25 |

1" |

33.4 |

2.77 |

|

2.9 |

3.38 |

3.38 |

|

4.55 |

4.55 |

|

|

|

6.35 |

9.09 |

|

32 |

1.1/4" |

42.2 |

2.77 |

|

2.97 |

3.56 |

3.56 |

|

4.85 |

4.85 |

|

|

|

6.35 |

9.7 |

|

40 |

1.1/2" |

48.3 |

2.77 |

|

3.18 |

3.68 |

3.68 |

|

5.08 |

5.08 |

|

|

|

7.14 |

10.15 |

|

50 |

2" |

60.3 |

2.77 |

|

3.18 |

3.91 |

3.91 |

|

5.54 |

5.54 |

|

|

|

8.74 |

11.07 |

|

65 |

2.1/2" |

73 |

3.05 |

|

4.78 |

5.16 |

5.16 |

|

7.01 |

7.01 |

|

|

|

9.53 |

14.02 |

|

80 |

3" |

88.9 |

3.05 |

|

4.78 |

5.49 |

5.49 |

|

7.62 |

7.62 |

|

|

|

11.13 |

15.25 |

|

90 |

3.1/2" |

101.6 |

3.05 |

|

4.78 |

5.74 |

5.74 |

|

8.08 |

8.08 |

|

|

|

|

|

|

100 |

4" |

114.3 |

3.05 |

|

4.78 |

6.02 |

6.02 |

|

8.56 |

8.56 |

|

11.13 |

|

13.49 |

17.12 |

|

125 |

5" |

141.3 |

3.4 |

|

|

6.55 |

6.55 |

|

9.53 |

9.53 |

|

12.7 |

|

15.88 |

19.05 |

|

150 |

6" |

168.3 |

3.4 |

|

|

7.11 |

7.11 |

|

10.97 |

10.97 |

|

14.27 |

|

18.26 |

21.95 |

|

200 |

8" |

219.1 |

3.76 |

6.35 |

7.04 |

8.18 |

8.18 |

10.31 |

12.7 |

12.7 |

15.09 |

18.26 |

20.62 |

23.01 |

22.23 |

|

250 |

10" |

273 |

4.19 |

6.35 |

7.8 |

9.27 |

9.27 |

12.7 |

12.7 |

15.09 |

18.26 |

21.44 |

25.4 |

28.58 |

25.4 |

|

300 |

12" |

323.8 |

4.57 |

6.35 |

8.38 |

9.53 |

10.31 |

14.27 |

12.7 |

17.48 |

21.44 |

25.4 |

28.58 |

33.32 |

25.4 |

|

350 |

14" |

355.6 |

6.35 |

7.92 |

9.53 |

9.53 |

11.13 |

15.09 |

12.7 |

19.05 |

23.83 |

27.79 |

31.75 |

35.71 |

|

|

400 |

16" |

406.4 |

6.35 |

7.92 |

9.53 |

9.53 |

12.7 |

16.66 |

12.7 |

21.44 |

26.19 |

30.96 |

36.53 |

40.19 |

|

|

450 |

18" |

457.2 |

6.35 |

7.92 |

11.13 |

9.53 |

14.27 |

19.05 |

12.7 |

23.83 |

39.36 |

34.93 |

39.67 |

45.24 |

|

|

500 |

20" |

508 |

6.35 |

9.53 |

12.7 |

9.53 |

15.09 |

20.62 |

12.7 |

26.19 |

32.54 |

38.1 |

44.45 |

50.01 |

|

|

550 |

22" |

558.8 |

6.35 |

9.53 |

12.7 |

9.53 |

|

22.23 |

12.7 |

28.58 |

34.93 |

41.28 |

47.63 |

53.98 |

|

|

600 |

24" |

609.6 |

6.35 |

9.53 |

14.27 |

9.53 |

17.48 |

24.61 |

12.7 |

30.96 |

38.89 |

46.02 |

52.37 |

59.54 |

|

|

650 |

26" |

660.4 |

7.92 |

12.7 |

|

9.53 |

|

|

12.7 |

|

|

|

|

|

|

|

700 |

28" |

711.2 |

7.92 |

12.7 |

15.88 |

9.53 |

|

|

12.7 |

|

|

|

|

|

|

|

750 |

30" |

762 |

7.92 |

12.7 |

15.88 |

9.53 |

|

|

12.7 |

|

|

|

|

|

|

|

800 |

32" |

812.8 |

7.92 |

12.7 |

15.88 |

9.53 |

17.48 |

|

12.7 |

|

|

|

|

|

|

|

850 |

34" |

863.6 |

7.92 |

12.7 |

15.88 |

9.53 |

17.48 |

|

12.7 |

|

|

|

|

|

|

|

900 |

36" |

914.4 |

7.92 |

12.7 |

15.88 |

9.53 |

19.05 |

|

12.7 |

|

|

|

|

|

|

|

API 5L |

for use in conveying gas, water, and oil in the natural gas and oil industries, and covers seamless and welded steel line pipe. |

|

API 5CT |

for casing and tubing |

|

ASTM A53 |

for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

|

ASTM A106 |

for Seamless Carbon Steel Pipe for High-Temperature Service |

|

ASTM A179 |

for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes |

|

ASTM A192 |

for Seamless Carbon Steel Boiler Tubes for High-Pressure Service |

|

ASTM A213 |

for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes |

|

ASTM A252 |

for Welded and Seamless Steel Pipe Piles |

|

ASTM A333 |

for Seamless and Welded Steel Pipe for Low-Temperature Service and Other Applications with Required Notch Toughness |

|

ASTM A672 |

for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures |

|

ASTM A335 |

for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service |

|

DIN 17175 |

seamless steel pipes are used in boiler installations, high-pressure pipelines and tank construction and special machinery for both high temperature and high-pressure devices. |

|

DIN 1629 |

specifies the Seamless Circular Tubes of Non Alloys Steels with Special Quality Requirements. |

|

DIN 2391 |

for Cold Drawn High Precision Seamless Tube |

|

DIN 2458 |

Welded Steel Pipes in Unalloyed and Low Alloy Steels for Supply Purposes |

|

EN 10210 |

Seamless steel tubes for pressure purposes |

|

BS 3059 |

Steel boiler and superheater tubes |

|

JIS G3454 |

Carbon steel pipes for pressure service |

|

specification |

Grade |

Chemical Composition [%] |

||||||||||||||||

|

C |

Mn |

P |

S |

Si |

Cr |

Mo |

Cu |

Ni |

V |

|||||||||

|

Min |

Max. |

Min |

Max. |

Max. |

Max. |

Min. |

Max |

Min. |

Max |

Min. |

Max |

Max |

Max |

Max |

||||

|

HYDROCARBON PROCESS INDUSTRY/STRUCTURAL/PRESSURE VESSEL TUBES |

||||||||||||||||||

|

ASTM A-53 |

A |

- - |

0.25 0.30 |

- - |

0.95 1.20 |

0.050 0.050 |

0.045 0.045 |

- - |

- - |

- - |

0.40 0.40 |

- - |

0.15 0.15 |

0.40 for S 0.40 for S |

0.40 0.40 |

0.08 0.08 |

||

|

ASTM A-106 |

A c |

- - - |

0.25 0.30 0.35 |

0.27 0.29 0.29 |

0.93 1.06 1.06 |

0.035 0.035 0.035 |

0.035 0.035 0.035 |

0.10 0.10 0.10 |

- - - |

- - - |

0.40 0.40 0.40 |

- - - |

0.15 0.15 0.15 |

0.40 0.40 0.40 |

0.40 -

|

0.08 0.08 0.08 |

||

|

ASTM A333 & A 334 |

1 |

- |

0.30 0.30 |

0.40 0.29 |

1.06 1.06 |

0.025 0.025 |

0.025 0.025 |

- 0.10 |

- - |

- - |

- - |

- - |

- - |

- - |

- - |

- - |

||

|

SEAMLESS COLD DRAWN PRECISION STEEL TUBES FOR MECHANICAL APPLICATIONS/HYDRAULIC/PNEUMATIC POWER SYSTEMS |

||||||||||||||||||

|

EN 10305-1/ EN10305-4 |

E 235 E 355 |

|

0.17 0.22 |

|

1.2 1.6 |

0.025 0.025 |

0.025 0.025 |

|

0.35 0.55 |

|

|

|

|

|

|

0.02 0.02 |

||

|

EN 10216-1 |

P195 TR1 |

|

0.13 0.16 |

|

0.7 1.2 |

0.025 0.025 |

0.02 0.02 |

|

0.35 0.35 |

|

0.3 0.3 |

|

0.08 0.08 |

0.3 0.3 |

0.3 0.3 |

|

||

|

EN 10216-2 |

P235 GH |

|

0.16 |

|

1.2 |

0.025 |

0.02 |

|

0.35 |

|

0.3 |

|

0.08 |

0.3 |

0.3 |

0.02 |

||

|

DIN 2391 |

St - 45 |

- |

0.17 0.21 0.22 |

0.40 0.40 - |

- - 1.60 |

0.025 0.025 0.025 |

0.025 0.025 0.025 |

- - - |

0.35 0.35 0.55 |

- - - |

- - - |

- - - |

- - - |

- - - |

- - - |

- - - |

||

|

ASTM A-519 |

SAE 1010 SAE 1040 SAE 1518 SAE 1541 SAE 4130 |

0.08 0.15 0.22 0.32 0.37 0.15 0.36 0.28 |

0.13 0.20 0.28 0.38 0.44 0.21 0.44 0.33 |

0.30 0.60 0.60 0.60 0.60 1.10 1.35 0.40 |

0.60 0.90 0.90 0.90 0.90 1.40 1.65 0.60 |

0.040 0.040 0.040 0.040 0.040 0.040 0.040 0.040 |

0.050 0.050 0.050 0.050 0.050 0.050 0.050 0.040 |

- - - - - - - 0.15 |

- - - - - - - 0.35 |

- - - - - - - 0.80 |

- - - - - - - 1.10 |

- - - - - - - 0.15 |

- - - - - - - 0.25 |

- - - - - - - - |

- - - - - - - - |

- - - - - - - - |

||

|

BOILER/HEAT EXCHANGER/SUPERHEATER & CONDENSER TUBES |

||||||||||||||||||

|

ASTM A179 |

- |

0.06 |

0.18 |

0.27 |

0.63 |

0.035 |

0.035 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

|

ASTM A192 |

|

0.06 |

0.18 |

0.27 |

0.63 |

0.035 |

0.035 |

- |

0.25 |

- |

- |

- |

- |

- |

- |

- |

|

|

|

ASTM A 210 |

A-1 |

- |

0.27 0.35 |

- 0.29 |

0.93 1.06 |

0.035 0.035 |

0.035 0.035 |

0.10 0.10 |

- - |

- - |

- - |

- - |

- - |

- - |

- - |

- - |

|

|

|

ASTM A 213 |

T-11 T-22 |

0.05 0.05 0.05 |

0.15 0.15 0.15 |

0.30 0.30 0.30 |

0.60 0.61 0.60 |

0.025 0.025 0.025 |

0.025 0.025 0.025 |

0.50 - - |

1.00 0.50 0.50 |

1.00 0.80 1.90 |

1.50 1.25 2.60 |

0.44 0.44 0.87 |

0.65 0.65 1.13 |

- - - |

- - - |

- - - |

|

|

|

ASTM |

P-11 P-22 |

0.05 0.05 0.05 |

0.15 0.15 0.15 |

0.30 0.30 0.30 |

0.60 0.61 0.60 |

0.025 0.025 0.025 |

0.025 0.025 0.025 |

0.50 - - |

1.00 0.50 0.50 |

1.00 0.80 1.90 |

1.50 1.25 2.60 |

0.44 0.44 0.87 |

0.65 0.65 1.13 |

- - - |

- - - |

- - - |

|

|

|

BS 3059 Pt I |

320 |

- |

0.16 |

0.30 |

0.70 |

0.040 |

0.040 |

0.10 |

0.35 |

- |

- |

- |

- |

- |

- |

- |

|

|

|

BS 3059 Pt II |

622-490 |

0.08 |

0.15 |

0.40 |

0.70 |

0.030 |

0.030 |

- |

0.50 |

2.00 |

2.50 |

0.90 |

1.20 |

- |

- |

- |

|

|

|

DIN 1629 |

St- 37.0 St - 52 |

- - |

0.17 0.22 |

- - |

- - |

0.040 0.040 |

0.040 0.035 |

- - |

- - |

- - |

- - |

- - |

- - |

- - |

- - |

- - |

|

|

|

DIN 17175 |

St - 35.8 St - 45.8 |

- - |

0.17 0.21 |

0.40 0.40 |

0.80 1.20 |

0.040 0.040 |

0.040 0.040 |

0.10 0.10 |

0.35 0.35 |

- - |

- - |

- - |

- - |

- - |

- - |

- - |

|

|

|

RAILWAYS |

||||||||||||||||||

|

IS:1239 Pt I |

- |

- |

- |

- |

- |

0.050 |

0.050 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

|

IS:1161 |

YST-210 YST-240 YST-310 |

- - - |

0.12 0.16 0.25 |

- - - |

0.60 1.20 1.30 |

0.040 0.040 0.040 |

0.040 0.040 0.040 |

- - - |

- - - |

- - - |

- - - |

- - - |

- - - |

- - - |

- - - |

- - - |

|

|

|

|

Grade A |

Grade B |

Grade C |

|

Tensile strength, min, psi (MPa) |

48,000 (330) |

60000 (415) |

70,000 (485) |

|

Yield strength, min, psi (MPa) |

30,000 (205) |

35,000 (240) |

40,000 (275) |

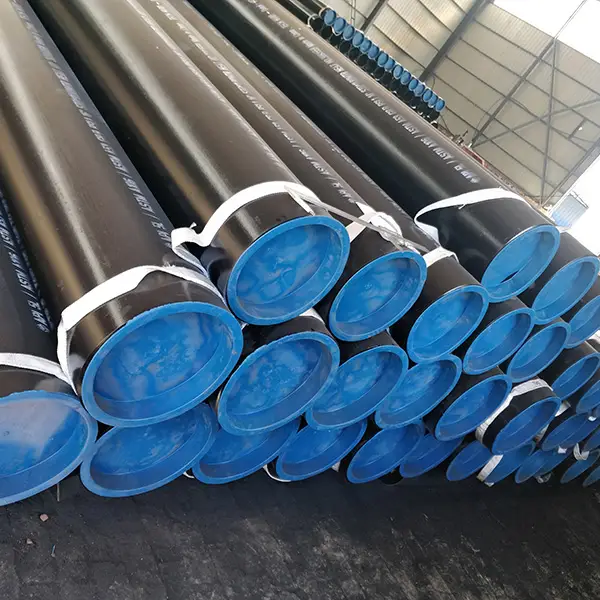

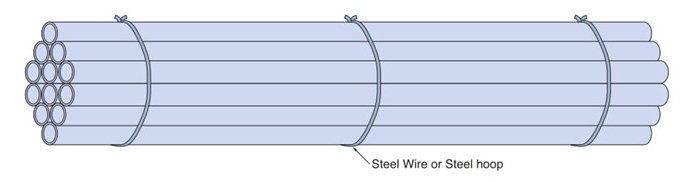

Bundled package

On bundle of steel tube shall be the same in batch number, steel grade and specification.the rest of tubing less than one bundle should be tied into small bundles.

The weight of each bundle should be less than 50kg.The max weight cannot exceed 80kg of the bundle If there are special requirements.

When the length of the steel tube is greater than or equal to 6m, with at least 8 strapping bands for each bundle, divided into 3 groups and 3-2-3.

When the length of the steel tube is less than 6m, and each bundle is tied at least 5 knots and divided into 3 groups, which are 2-1-2.

When the length of the tube is greater than or equal to 3m, and each bundle is tied with at least 3 bands, divided into 3 groups, 1-1-1 showed below

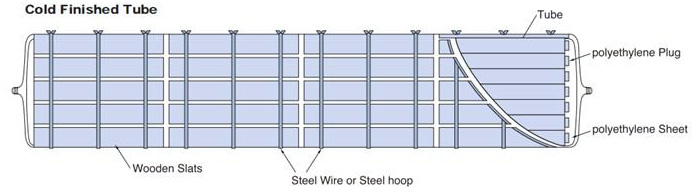

Wooden box package

The wooden box is suitable for cold rolling or cold drawing seamless steel tube, polished hot rolled stainless steel tube.

When the outer diameter of steel pipe is greater than or equal 10mm, the maximum weight of the container should be 50kg.

When the outer diameter of steel pipe is less than or equal 10mm, the maximum weight of the container should be 30kg.