We are committed to providing one-stop service for steel pipe products to customers around the world.

Casing and tubing couplings are mechanical devices used to connect two sections of casing or tubing pipes together in oil and gas drilling and production operations.

Casing and tubing couplings are typically made of high-strength steel and are threaded on both ends to allow them to be screwed onto the end of each pipe section. The threads on the coupling are designed to match the threads on the pipe ends, providing a tight seal and maintaining the structural integrity of the wellbore.

API CASING COUPLINGS - SHORT THREAD (STC)

|

API Casing Couplings Short Thread |

Casing Size OD (inches) |

Coupling Size OD (inches) |

Length (inches) |

Weight per Coupling (lbs) |

Palletized Carton Quantity |

Palletized Carton Weight |

|

|

4-1/2 |

5.000 |

6.250 |

8.05 |

343 |

2716 |

|

5 |

5.563 |

6.500 |

10.18 |

210 |

2168 |

|

|

5-1/2 |

6.050 |

6.750 |

11.44 |

216 |

2501 |

|

|

6-5/8 |

7.390 |

7.250 |

19.97 |

115 |

2322 |

|

|

7 |

7.656 |

7.250 |

18.34 |

120 |

2231 |

|

|

7-5/8 |

8.500 |

7.500 |

26.93 |

80 |

2322 |

|

|

8-5/8 |

9.625 |

7.750 |

35.58 |

60 |

2132 |

|

|

9-5/8 |

10.625 |

7.750 |

39.51 |

50 |

2006 |

|

|

10-3/4 |

11.750 |

8.000 |

49.61 |

45 |

2079 |

|

|

11-3/4 |

12.750 |

8.000 |

50.49 |

35 |

1767 |

|

|

13-3/8 |

14.375 |

8.000 |

56.23 |

25 |

1436 |

|

|

16 |

17.000 |

9.000 |

78.98 |

20 |

- |

|

|

18-5/8 |

20 |

9.000 |

118.94 |

10 |

- |

|

|

20 |

21.000 |

9.000 |

98.25 |

10 |

- |

API CASING COUPLINGS - LONG THREAD (LTC)

|

API Casing Couplings Long Thread |

Casing Size OD (inches) |

Coupling Size OD (inches) |

Length (inches) |

Weight per Coupling (lbs) |

Palletized Carton Quantity |

Palletized Carton Weight |

|

|

4-1/2 |

5.000 |

7.000 |

9.07 |

294 |

2697 |

|

5 |

5.563 |

7.750 |

12.56 |

210 |

2573 |

|

|

5-1/2 |

6.050 |

8.000 |

14.03 |

180 |

2555 |

|

|

6-5/8 |

7.390 |

8.750 |

24.82 |

100 |

2315 |

|

|

7 |

7.656 |

9.000 |

23.67 |

100 |

2351 |

|

|

7-5/8 |

8.500 |

9.250 |

34.23 |

80 |

2807 |

|

|

8-5/8 |

9.625 |

10.000 |

47.48 |

48 |

2337 |

|

|

9-5/8 |

10.625 |

10.500 |

55.77 |

40 |

2302 |

|

|

10-3/4 |

11.750 |

* 10.500 |

* 62.38 |

45 |

* 36 |

|

|

11-3/4 |

12.750 |

* 10.500 |

* 67.59 |

30 |

* 24 |

|

|

13-3/8 |

14.375 |

* 10.500 |

* 76.63 |

25 |

* 20 |

|

|

16 |

17.000 |

* 11.000 |

* 96.55 |

20 |

* 16 |

|

|

18-5/8 |

20.000 |

- |

- |

10 |

8 |

|

|

20 |

21.000 |

* 11.500 |

* 126.74 |

10 |

8 |

|

|

* NOT API SPECIFICATIONS. |

||||||

API CASING COUPLINGS - BUTTRESS THREAD (BTC)

|

API Casing Couplings Buttress Thread |

Casing Size OD (inches) |

Coupling Size OD (inches) |

Length (inches) |

Weight per Coupling (lbs) |

Palletized Carton Quantity |

Palletized Carton Weight |

|

|

4-1/2 |

5.000 |

8.875 |

10.11 |

196 |

2007 |

|

5 |

5.563 |

9.125 |

12.99 |

144 |

2840 |

|

|

5-1/2 |

6.050 |

9.250 |

14.14 |

144 |

2061 |

|

|

6-5/8 |

7.390 |

9.625 |

24.46 |

92 |

2295 |

|

|

7 |

7.656 |

10.000 |

23.22 |

80 |

2068 |

|

|

7-5/8 |

8.500 |

10.375 |

64.84 |

64 |

2221 |

|

|

8-5/8 |

9.625 |

10.625 |

45.94 |

48 |

2414 |

|

|

9-5/8 |

10.625 |

10.625 |

50.99 |

40 |

2256 |

|

|

10-3/4 |

11.750 |

10.625 |

56.68 |

36 |

2307 |

|

|

11-3/4 |

12.750 |

10.625 |

61.74 |

24 |

2179 |

|

|

13-3/8 |

14.375 |

10.625 |

69.95 |

20 |

1429 |

|

|

16 |

17.000 |

10.625 |

87.56 |

16 |

- |

|

|

18-5/8 |

20.000 |

10.625 |

138.03 |

8 |

- |

|

|

20 |

21.000 |

10.625 |

110.33 |

8 |

- |

API TUBING COUPLINGS - EXTERNAL UPSET END (EUE)

|

API EUE Tubing Couplings |

Casing Size OD (inches) |

Coupling Size OD (inches) |

Threads per inch |

Length (inches) |

Weight per Coupling (lbs) |

Palletized Carton Quantity |

Palletized Carton Weight |

|

|

1.90 |

2.500 |

10 Round |

- |

1.85 |

- |

- |

|

2-3/8 |

3.063 |

8 Round |

4.875 |

3.42 |

1,444 |

3942 |

|

|

2-7/8 |

3.668 |

8 Round |

5.500 |

5.29 |

792 |

4220 |

|

|

3-1/2 |

4.500 |

8 Round |

5.750 |

9.02 |

448 |

3860 |

|

|

4 |

5.000 |

8 Round |

- |

10.62 |

392 |

- |

|

|

4-1/2 |

5.563 |

8 Round |

6.500 |

13.31 |

252 |

3456 |

API TUBING COUPLINGS - NON UPSET END (NUE)

|

API Non-Upset Tubing Couplings |

Casing Size OD (inches) |

Coupling Size OD (inches) |

Threads per inch |

Length (inches) |

Weight per Coupling (lbs) |

Palletized Carton Quantity |

Palletized Carton Weight |

|

|

1.90 |

2.200 |

10 Round |

3.750 |

1.85 |

- |

- |

|

2-3/8 |

2.875 |

10 Round |

4.500 |

2.82 |

1,512 |

4264 |

|

|

2-7/8 |

3.500 |

10 Round |

5.500 |

5.15 |

800 |

4120 |

|

|

3-1/2 |

4.250 |

10 Round |

5.625 |

8.17 |

502 |

4101 |

|

|

4 |

4.75 |

8 Round |

5.75 |

9.57 |

392 |

- |

|

|

4-1/2 |

5.200 |

8 Round |

6.500 |

10.76 |

252 |

2712 |

COUPLING PIPE GRADE IDENTIFICATION BY PAINT COLOR

|

Grade |

Colour Coding (Painted Outside) |

|

H-40 |

Black |

|

J-55 or K-55 |

Green |

|

N-80 |

Red |

|

M-65 or L-80 |

Red with one Brown Band |

|

L-80 Type 9CR |

Red with two Yellow Bands |

|

L-80 Type 13CR |

Red with one Yellow Band |

|

C-90 Type 1 |

Purple |

|

C-90 Type 2 |

Purple with one Yellow Band |

|

T-95 Type 1 |

Silver |

|

T-95 Type 2 |

Silver with one Yellow Band |

|

C-95 |

Brown |

|

P-110 |

White |

|

Q-125 Type 1 |

Orange |

|

Q-125 Type 2 |

Orange with one Yellow Band |

|

Q-125 Type 3 |

Orange with one Green Band |

|

Q-125 Type 4 |

Orange with one Brown Band |

Specification

|

Size |

Type of Thread |

O.D*L (mm) |

Weight (kg) |

|

2-3/8" |

NUE |

73.02*107.95 |

1.28 |

|

2-3/8" |

EUE |

77.80*132.82 |

1.55 |

|

2-7/8" |

NUE |

88.90*130.18 |

2.34 |

|

2-7/8" |

EUE |

93.17*133.35 |

2.4 |

|

3-1/2" |

NUE |

107.95*142.88 |

3.71 |

|

3-1/2" |

EUE |

114.30*146.05 |

4.1 |

|

4" |

NUE |

120.65*146.05 |

4.35 |

|

4" |

EUE |

127.00*152.40 |

4.82 |

|

4-1/2" |

NUE |

132.08*155.58 |

4.89 |

|

4-1/2" |

EUE |

141.30*158.75 |

6.05 |

|

Couplings |

Size in |

Max. OD in(mm) |

Min length in(mm) |

Grade |

||

|

|

|

NU |

EU |

NU |

EU |

|

|

|

23/8 |

2.875(73.03) |

3.063(77.80) |

41/4(107.95) |

47/8(123.83) |

J55 |

|

|

27/8 |

3.500(88.90) |

3.668(93.20) |

51/8(130.18) |

51/4(133.35) |

|

|

|

31/2 |

4.250(108.00) |

4.500(114.30) |

55/8(142.88) |

53/4(146.05) |

|

|

Crossovers |

J55,N80,L80 All kinds of crossovers, connections and sub-couplings of grades J55, N80 and L80 |

|||||

COUPLING PIPE GRADE IDENTIFICATION BY PAINT COLOR

According to API 5CT standards, Oil casing and Tubing couplings should be painted one by one to distinguish different grades of steel. The color label of the oil casing and Tubing should be sprayed at any end ≥ 600mm, and the color should be painted on the whole outer surface, and then the color ring should be sprayed.

|

Coupling colour code |

|||||

|

Grade |

Grade Type |

Colour(s) for Coupling |

Number andcolour of bandsfor product |

Picture |

|

|

EntireCoupling |

Band(s) |

||||

|

H40 |

|

None |

Same as for pipe |

None/black band at the manufacturer’s option |

|

|

J55 Tubing |

|

Bright Green |

None |

One Bright Green |

|

|

J55 Casing |

|

Bright Green |

One White |

One Bright Green |

|

|

K55 |

|

Bright Green |

None |

Two Bright Green |

|

|

M65 |

|

M65Pipe uses L80Type 1Couplings |

One Bright GreenOne Blue |

|

|

|

N80 |

1 |

Red |

None |

One Red |

|

|

N80 |

Q |

Red |

One Green |

One RedOne Bright Green |

|

|

R95 |

|

Brown |

None |

One Brown |

|

|

L80 |

1 |

Red |

One Brown |

One RedOne Brown |

|

|

L80 |

9Cr |

None |

Two Yellow |

One Red,One Brown,Two Yellow |

|

|

L80 |

13Cr |

None |

One Yellow |

One Red,One Brown,One Yellow |

|

|

C90 |

1 |

Purple |

None |

One Purple |

|

|

T95 |

1 |

Silver |

None |

One Silver |

|

|

C110 |

|

White |

Two Brown |

One White,Two Brown |

|

|

P110 |

|

White |

None |

One White |

|

|

Q125 |

|

Orange |

None |

One Orange |

|

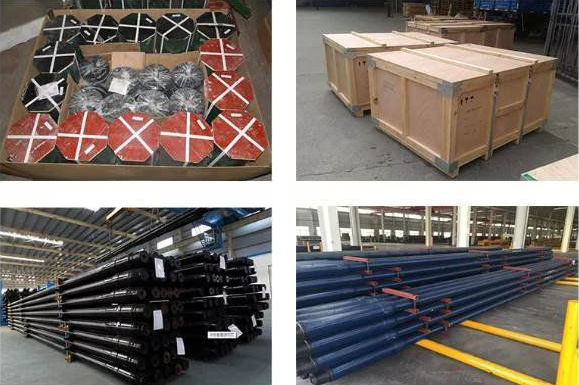

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

● Plastic caps plugged at the two sides of pipe ends

● Should be avoided by the steel strapping and transport damage

● Bundled signs should be uniform and consistent

● The same bundle(batch) of steel pipe should be came from the same furnace.

● The steel pipe has the same furnace number, the same steel grade, the same specifications.

Our packing can meet any needs of the customers.