We are committed to providing one-stop service for steel pipe products to customers around the world.

Alloy steel seamless pipe is ideally suitable for chemical, petrochemicals and other energy-related applications.They can be used in high-temperature and high-pressure environments, and they are also known for their excellent resistance to corrosion.

- Chemical industries

- Petrochemical industries

- Energy-related applications

|

Size Range |

1/8" –42” |

|

Schedules |

20, 30, 40, Standard (STD), Extra Heavy (XH), 80, 100, 120, 140, 160, XXH & heavier |

|

Standard |

ASTM A335, ASTM A213 etc |

|

Grade |

ASTM A335 P1, P2, P5, P9, P11, P12, P22, P23, P91, P92, ASTM A213 T2, T5, T5b, T5c, T9, T11, T12, T22, T23, T91, T92 |

|

ASTM /ASME |

|||

|

Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

|

Seamless Ferritic and Austentic Alloy Steel Boiler, Superheater and Heat-Exchanger Tubes |

ASTM A213 |

Ø10.3~426 x WT1.0~36 |

T5, T9, T11, T12, T22, T91 |

|

Seamless Ferritic Alloy Steel Pipes for High Temperature Use |

ASTM A335 |

Ø1/4"~42" x WT2~120mm |

P5, P9, P11, P12, P22, P91, P92 |

|

Seamless Carbon and Alloy Steel for Mechanical Tubing |

ASTM A519 |

Ø16"~42" x WT10~100mm |

4130, 4130X, 4140 |

|

EN |

|||

|

Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

|

Seamless Ferritic Alloy Steel Pipes for High Temperature Use |

EN10216-2 |

Ø8"~42" x WT15~100 |

13CrMo4-5, 1-CrMo9-10, X10CrMoVNb9-1, 15NiCuMoNb5-6-4 |

Outside Diameter & Tolerance :

|

Hot rolled |

Outside Diameter, mm |

Tolerance, mm |

|

OD≤101.6 |

+0.4/-0.8 |

|

|

101.6<OD≤190.5 |

+0.4/-1.2 |

|

|

190.5<OD≤228.6 |

+0.4/-1.6 |

|

|

Cold Drawn |

Outside Diameter, mm |

Tolerance, mm |

|

OD<25.4 |

±0.10 |

|

|

25.4≤OD≤38.1 |

±0.15 |

|

|

38.1<OD<50.8 |

±0.20 |

|

|

50.8≤OD<63.5 |

±0.25 |

|

|

63.5≤OD<76.2 |

±0.30 |

|

|

76.2≤OD≤101.6 |

±0.38 |

|

|

101.6<OD≤190.5 |

+0.38/-0.64 |

|

|

190.5<OD≤228.6 |

+0.38/-1.14 |

Wall thickness & Tolerance

|

Hot rolled |

Outside Diameter, mm |

Tolerance, % |

|

OD≤101.6, WT≤2.4 |

+40/-0 |

|

|

OD≤101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD≤101.6, 3.8<WT≤4.6 |

+33/-0 |

|

|

OD≤101.6, WT>4.6 |

+28/-0 |

|

|

OD>101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD>101.6, 3.8<WT≤4.6 |

+33/-0 |

|

|

OD>101.6, WT>4.6 |

+28/-0 |

|

|

Cold Drawn |

Outside Diameter, mm |

Tolerance, % |

|

OD≤38.1 |

+20/-0 |

|

|

OD>38.1 |

+22/-0 |

|

Size Range |

1/8" –42” |

|

Schedules |

20, 30, 40, Standard (STD), Extra Heavy (XH), 80, 100, 120, 140, 160, XXH & heavier |

|

Standard |

ASTM A335, ASTM A213 etc |

|

Grade |

ASTM A335 P1, P2, P5, P9, P11, P12, P22, P23, P91, P92, ASTM A213 T2, T5, T5b, T5c, T9, T11, T12, T22, T23, T91, T92 |

|

ASTM /ASME |

|||

|

Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

|

Seamless Ferritic and Austentic Alloy Steel Boiler, Superheater and Heat-Exchanger Tubes |

ASTM A213 |

Ø10.3~426 x WT1.0~36 |

T5, T9, T11, T12, T22, T91 |

|

Seamless Ferritic Alloy Steel Pipes for High Temperature Use |

ASTM A335 |

Ø1/4"~42" x WT2~120mm |

P5, P9, P11, P12, P22, P91, P92 |

|

Seamless Carbon and Alloy Steel for Mechanical Tubing |

ASTM A519 |

Ø16"~42" x WT10~100mm |

4130, 4130X, 4140 |

|

EN |

|||

|

Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

|

Seamless Ferritic Alloy Steel Pipes for High Temperature Use |

EN10216-2 |

Ø8"~42" x WT15~100 |

13CrMo4-5, 1-CrMo9-10, X10CrMoVNb9-1, 15NiCuMoNb5-6-4 |

Chemical Composition

|

Grade |

UNS |

C= |

Mn |

P= |

S= |

Si= |

Cr |

Mo |

|

P1 |

K11522 |

0.10~ 0.20 |

0.30~ 0.80 |

0.025 |

0.025 |

0.10~ 0.50 |

- |

0.44~ 0.65 |

|

P2 |

K11547 |

0.10~ 0.20 |

0.30~ 0.61 |

0.025 |

0.025 |

0.10~ 0.30 |

0.50~ 0.81 |

0.44~ 0.65 |

|

P5 |

K41545 |

0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

4.00~ 6.00 |

0.44~ 0.65 |

|

P5b |

K51545 |

0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

1.00~ 2.00 |

4.00~ 6.00 |

0.44~ 0.65 |

|

P5c |

K41245 |

0.12 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

4.00~ 6.00 |

0.44~ 0.65 |

|

P9 |

S50400 |

0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.50~ 1.00 |

8.00~ 10.00 |

0.44~ 0.65 |

|

P11 |

K11597 |

0.05~ 0.15 |

0.30~ 0.61 |

0.025 |

0.025 |

0.50~ 1.00 |

1.00~ 1.50 |

0.44~ 0.65 |

|

P12 |

K11562 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

0.80~ 1.25 |

0.44~ 0.65 |

|

P15 |

K11578 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

1.15~ 1.65 |

- |

0.44~ 0.65 |

|

P21 |

K31545 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

2.65~ 3.35 |

0.80~ 1.60 |

|

P22 |

K21590 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

1.90~ 2.60 |

0.87~ 1.13 |

|

P91 |

K91560 |

0.08~ 0.12 |

0.30~ |

0.02 |

0.01 |

0.20~ 0.50 |

8.00~ 9.50 |

0.85~ 1.05 |

|

0.6 |

||||||||

|

P92 |

K92460 |

0.07~ 0.13 |

0.30~ 0.60 |

0.02 |

0.01 |

0.5 |

8.50~ 9.50 |

0.30~ 0.60 |

Mechanical Properties

|

Tensile Strength, MPa |

Yield Strength, MPa |

Elongation, % |

|

415 min |

205 min |

30 min |

|

Size Range |

1/8" –42” |

|

Schedules |

20, 30, 40, Standard (STD), Extra Heavy (XH), 80, 100, 120, 140, 160, XXH & heavier |

|

Standard |

ASTM A335, ASTM A213 etc |

|

Grade |

ASTM A335 P1, P2, P5, P9, P11, P12, P22, P23, P91, P92, ASTM A213 T2, T5, T5b, T5c, T9, T11, T12, T22, T23, T91, T92 |

|

ASTM /ASME |

|||

|

Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

|

Seamless Ferritic and Austentic Alloy Steel Boiler, Superheater and Heat-Exchanger Tubes |

ASTM A213 |

Ø10.3~426 x WT1.0~36 |

T5, T9, T11, T12, T22, T91 |

|

Seamless Ferritic Alloy Steel Pipes for High Temperature Use |

ASTM A335 |

Ø1/4"~42" x WT2~120mm |

P5, P9, P11, P12, P22, P91, P92 |

|

Seamless Carbon and Alloy Steel for Mechanical Tubing |

ASTM A519 |

Ø16"~42" x WT10~100mm |

4130, 4130X, 4140 |

|

EN |

|||

|

Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

|

Seamless Ferritic Alloy Steel Pipes for High Temperature Use |

EN10216-2 |

Ø8"~42" x WT15~100 |

13CrMo4-5, 1-CrMo9-10, X10CrMoVNb9-1, 15NiCuMoNb5-6-4 |

|

Hot rolled |

Outside Diameter, mm |

Tolerance, mm |

|

OD≤101.6 |

+0.4/-0.8 |

|

|

101.6<OD≤190.5 |

+0.4/-1.2 |

|

|

190.5<OD≤228.6 |

+0.4/-1.6 |

|

|

Cold Drawn |

Outside Diameter, mm |

Tolerance, mm |

|

OD<25.4 |

±0.10 |

|

|

25.4≤OD≤38.1 |

±0.15 |

|

|

38.1<OD<50.8 |

±0.20 |

|

|

50.8≤OD<63.5 |

±0.25 |

|

|

63.5≤OD<76.2 |

±0.30 |

|

|

76.2≤OD≤101.6 |

±0.38 |

|

|

101.6<OD≤190.5 |

+0.38/-0.64 |

|

|

190.5<OD≤228.6 |

+0.38/-1.14 |

Wall thickness & Tolerance

|

Hot rolled |

Outside Diameter, mm |

Tolerance, % |

|

OD≤101.6, WT≤2.4 |

+40/-0 |

|

|

OD≤101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD≤101.6, 3.8<WT≤4.6 |

+33/-0 |

|

|

OD≤101.6, WT>4.6 |

+28/-0 |

|

|

OD>101.6, 2.4<WT≤3.8 |

+35/-0 |

|

|

OD>101.6, 3.8<WT≤4.6 |

+33/-0 |

|

|

OD>101.6, WT>4.6 |

+28/-0 |

|

|

Cold Drawn |

Outside Diameter, mm |

Tolerance, % |

|

OD≤38.1 |

+20/-0 |

|

|

OD>38.1 |

+22/-0 |

Chemical Composition

|

Grade |

UNS |

C= |

Mn |

P= |

S= |

Si= |

Cr |

Mo |

|

P1 |

K11522 |

0.10~ 0.20 |

0.30~ 0.80 |

0.025 |

0.025 |

0.10~ 0.50 |

- |

0.44~ 0.65 |

|

P2 |

K11547 |

0.10~ 0.20 |

0.30~ 0.61 |

0.025 |

0.025 |

0.10~ 0.30 |

0.50~ 0.81 |

0.44~ 0.65 |

|

P5 |

K41545 |

0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

4.00~ 6.00 |

0.44~ 0.65 |

|

P5b |

K51545 |

0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

1.00~ 2.00 |

4.00~ 6.00 |

0.44~ 0.65 |

|

P5c |

K41245 |

0.12 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

4.00~ 6.00 |

0.44~ 0.65 |

|

P9 |

S50400 |

0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.50~ 1.00 |

8.00~ 10.00 |

0.44~ 0.65 |

|

P11 |

K11597 |

0.05~ 0.15 |

0.30~ 0.61 |

0.025 |

0.025 |

0.50~ 1.00 |

1.00~ 1.50 |

0.44~ 0.65 |

|

P12 |

K11562 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

0.80~ 1.25 |

0.44~ 0.65 |

|

P15 |

K11578 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

1.15~ 1.65 |

- |

0.44~ 0.65 |

|

P21 |

K31545 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

2.65~ 3.35 |

0.80~ 1.60 |

|

P22 |

K21590 |

0.05~ 0.15 |

0.30~ 0.60 |

0.025 |

0.025 |

0.5 |

1.90~ 2.60 |

0.87~ 1.13 |

|

P91 |

K91560 |

0.08~ 0.12 |

0.30~ |

0.02 |

0.01 |

0.20~ 0.50 |

8.00~ 9.50 |

0.85~ 1.05 |

|

0.6 |

||||||||

|

P92 |

K92460 |

0.07~ 0.13 |

0.30~ 0.60 |

0.02 |

0.01 |

0.5 |

8.50~ 9.50 |

0.30~ 0.60 |

Mechanical Properties

|

Tensile Strength, MPa |

Yield Strength, MPa |

Elongation, % |

|

415 min |

205 min |

30 min |

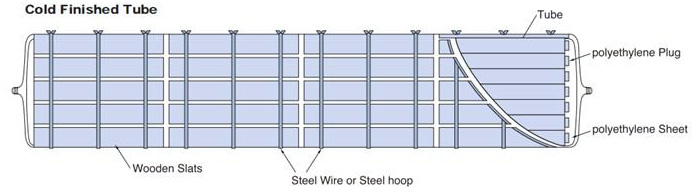

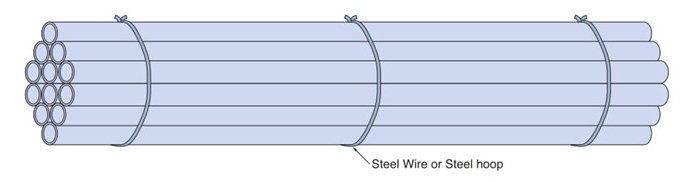

Bundled package

Wooden box package