We are committed to providing one-stop service for steel pipe products to customers around the world.

ERW steel pipe is Electric Resistance Welding, which is different from the welding process of ordinary welded pipe. The weld is formed by melting the base material of the steel strip body, and its mechanical strength is better than that of ordinary welded pipe.

ERW steel pipe has the advantages of using hot-rolled coil as raw material, the uniform wall thickness can be controlled at about ±0.2mm, the two ends of the steel pipe are in accordance with the American APL 5L standard or GB/T9711.1 standard, the pipe end is beveled, and the length is delivered. Etc. In recent years, various natural gas pipeline network projects and gas companies have widely adopted ERW steel pipes as the main steel pipes in urban pipeline networks.

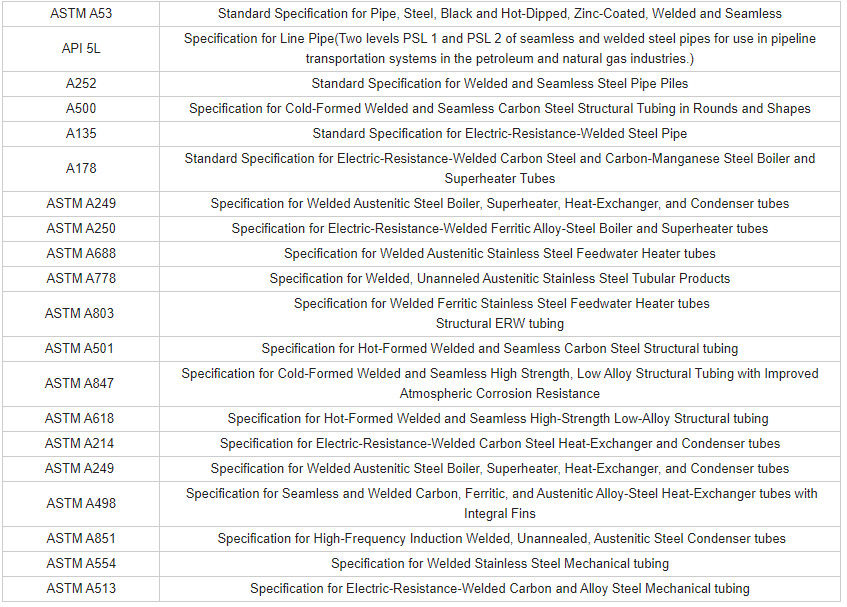

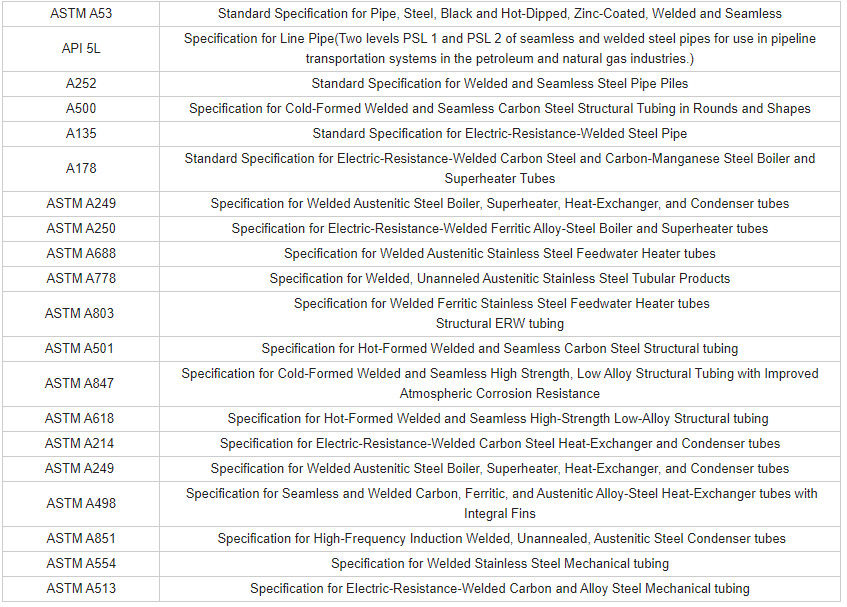

Standard:

ASTM 5L,ASTMA53,ASTM A178,ASTM A500/501,ASTM A691,ASTM A252,ASTMA672,EN 10217steel Grade:

API 5L: PSL1/PSL2 Gr.A,Gr.B,X42,X46, X52,X56, X60,X65,X70ASTM A53: GR.A,GR.B,ASTM A500 JIS G3466

EN: S275,S275JR,S355JRH,S355J2H,EN10219-1 ,EN10217-1GB:Q195,Q215,Q235,Q345,L175,L210,L245,L320,L360-L555

ASTM

5L,ASTMA53,ASTM A178,ASTM A500/501,ASTM A691,ASTM A252,ASTMA672,EN 10217steel

Grade:

API

5L: PSL1/PSL2 Gr.A,Gr.B,X42,X46, X52,X56, X60,X65,X70ASTM A53: GR.A,GR.B,ASTM

A500 JIS G3466

EN:

S275,S275JR,S355JRH,S355J2H,EN10219-1

,EN10217-1GB:Q195,Q215,Q235,Q345,L175,L210,L245,L320,L360-L555

Steel making in Converter → Refine → Continuous Casting → Hot Rolling → Uncoiling → Accumulator → Cross Welding → Strip End Shear → Strip Leveling → Edge Milling →Strip UT → Forming → Electric Resistance Welding → Sizing → Air Cooling+ Water Cooling → Online Weld Seam Heat Treatment → Online Weld SEAM UT → Bevelling → Hydrostatic Testing → Weld Seam UT → Pipe UT → Appearance and Dimension Check → Coating → Marking → Length-measuring and weighing → Packing → Transportation

Packing: Plastic plugs in both ends, Hexagonal bundles of max.2,0O0kg with several steel strips, Two tags on each bundle,Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

Test Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties(Flattening Test,Bending Test,Hardness Test, lmpact Test),Exterior Size Inspection, Hydrostatic Test,NDTTEST(ET TEST,RT TEST, UT TEST)