We are committed to providing one-stop service for steel pipe products to customers around the world.

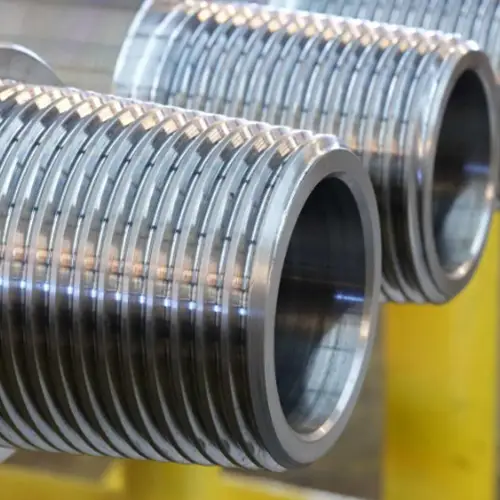

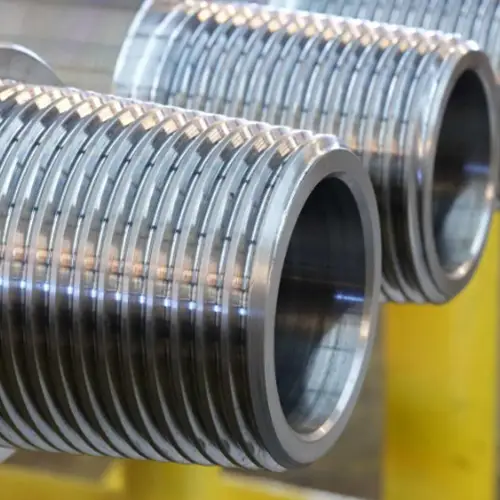

Drill pipe is a type of hollow steel pipe that is used in the drilling of oil and gas wells. It is typically used to transmit drilling fluid (mud) to the drill bit and to provide rotational power to the bit.

Drill pipe is an essential component of the drilling process and must be carefully selected to meet the specific requirements of the well. Factors such as size, weight, strength, and corrosion resistance must be taken into consideration to ensure the safety and productivity of the drilling operation.

● Drill Pipe

● 2-3/8" to 7-5/8" OD, Range 2 and 3

● Heavy Weigh

● 2-3/8" to 6-5/8" OD, Range 2 and 3

● Drill Collars

● 2-7/8" to 14"

Grades: E75, X95, G105, S135

Connection threads:NC26, NC31, NC38, NC40, NC46, NC50, 5 1/2FH.6 5/8FH.

Internal Upset: IU, EU, IEU

Heavy weight drill pipe is a medium-weight drilling pipe, (referred standards in API SPEC 7-1). It has bigger wall thickness than common drilling pipe and smaller than drill collar.

|

Size designation |

Calculated weight |

Tool joint designation |

Calculated weight |

grade |

Wall thickness |

Upset ends |

||

|

in |

1b/ft |

Kg/m |

in |

mm |

||||

|

2 3/8 |

6.65 |

NC26 |

6.26 |

9.32 |

E.X.G.S |

0.28 |

7.11 |

EU |

|

2 7/8 |

10.4 |

NC31 |

9.72 |

14.48 |

E.X.G.S |

0.362 |

9.19 |

EU |

|

3 1/2 |

13.3 |

NC38 |

12.31 |

18.34 |

E.X.G.S |

0.368 |

9.35 |

EU |

|

3 1/2 |

15.5 |

NC38,NC40 |

14.63 |

21.79 |

E.X.G.S |

0.449 |

11.4 |

EU |

|

4 |

14 |

NC40,NC46 |

12.93 |

19.26 |

E.X.G.S |

0.33 |

8.38 |

IU,EU |

|

4 1/2 |

16.6 |

NC46,NC50 |

14.98 |

22.31 |

E.X.G.S |

0.337 |

8.56 |

EU,IEU |

|

4 1/2 |

20 |

NC46,NC50 |

18.69 |

27.84 |

E.X.G.S |

0.43 |

10.92 |

EU,IEU |

|

5 |

19.5 |

NC50,NC52 |

17.93 |

26.71 |

E.X.G.S |

0.362 |

9.19 |

IEU |

|

5 |

25.6 |

NC50,5 1/2FH |

24.03 |

35.79 |

E.X.G.S |

0.5 |

12.7 |

IEU |

|

5 1/2 |

21.9 |

5 1/2FH |

19.81 |

29.51 |

E.X.G.S |

0.361 |

9.17 |

IEU |

|

5 1/2 |

24.7 |

5 1/2FH |

22.54 |

33.57 |

E.X.G.S |

0.415 |

10.54 |

IEU |

|

6 5/8 |

25.2 |

6 5/8FH |

22.19 |

33 |

E.X.G.S |

0.33 |

8.387 |

IEU |

|

6 5/8 |

27.7 |

6 5/8FH |

24.21 |

41 |

E.X.G.S |

0.362 |

9.19 |

IEU |

|

Item |

Tolerance |

|

|

Pipe Body |

OD≤101.6mm |

+0.79mm |

|

OD≥114.3mm |

+1% -0.5% |

|

|

Single Lengths |

-12.5% |

|

|

Weight |

+6.5% -3.5% |

|

Chemical Composition & Mechanical Properties

|

Grade |

Chemical Composition |

Mechanical Properties |

||

|

P |

S |

Yield Strength(Mpa) |

Tensile Strength(Mpa) |

|

|

E-75 |

≤0.020 |

≤0.015 |

517-724 |

≥689 |

|

X-95 |

≤0.020 |

≤0.015 |

655-862 |

≥724 |

|

G-105 |

≤0.020 |

≤0.015 |

724-931 |

≥793 |

|

S-135 |

≤0.020 |

≤0.015 |

931-1138 |

≥1000 |

|

Item |

Tolerance |

|

|

Pipe Body |

OD≤101.6mm |

+0.79mm |

|

OD≥114.3mm |

+1% -0.5% |

|

|

Single Lengths |

-12.5% |

|

|

Weight |

+6.5% -3.5% |

|

Chemical Composition & Mechanical Properties

|

Grade |

Chemical Composition |

Mechanical Properties |

||

|

P |

S |

Yield Strength(Mpa) |

Tensile Strength(Mpa) |

|

|

E-75 |

≤0.020 |

≤0.015 |

517-724 |

≥689 |

|

X-95 |

≤0.020 |

≤0.015 |

655-862 |

≥724 |

|

G-105 |

≤0.020 |

≤0.015 |

724-931 |

≥793 |

|

S-135 |

≤0.020 |

≤0.015 |

931-1138 |

≥1000 |

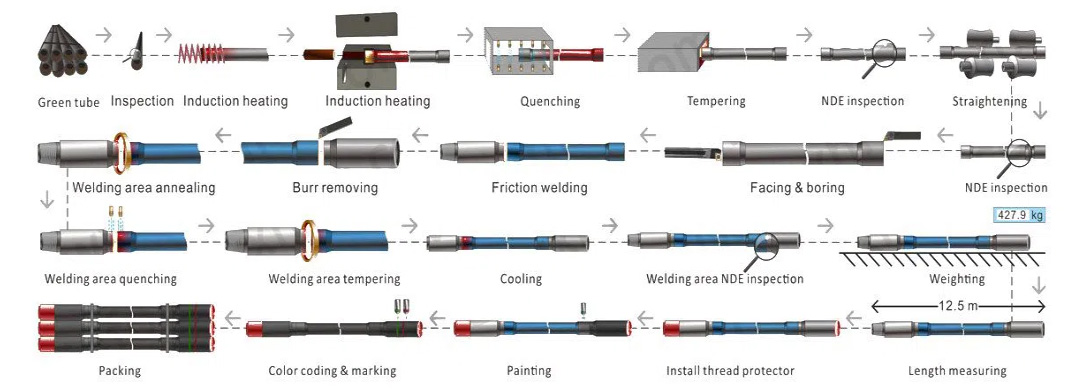

API SPEC 5DP specifies the technical delivery conditions for steel drill-pipes with upset pipe-body ends and weld-on tool joints for use in drilling and production operations in petroleum and natural gas industries for three product specification .

levels (PSL-1,PSL-2 and PSL-3).PS-1 specifies wall thickness, impact strength, and yield strength requirements specific to the material grade.Specification levels PL-2/PL-3 have additional mandatory requirements.

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

● Plastic caps plugged at the two sides of pipe ends

● Should be avoided by the steel strapping and transport damage

● Bundled signs should be uniform and consistent

● The same bundle(batch) of steel pipe should be came from the same furnace.

● The steel pipe has the same furnace number, the same steel grade, the same specifications.

Our packing can meet any needs of the customers.