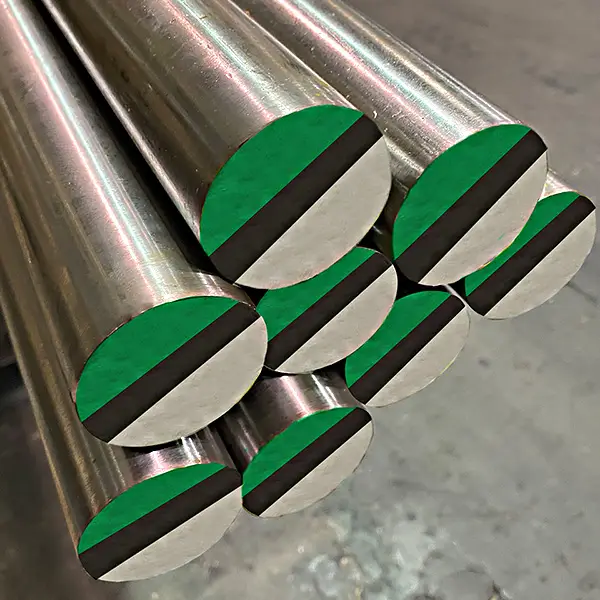

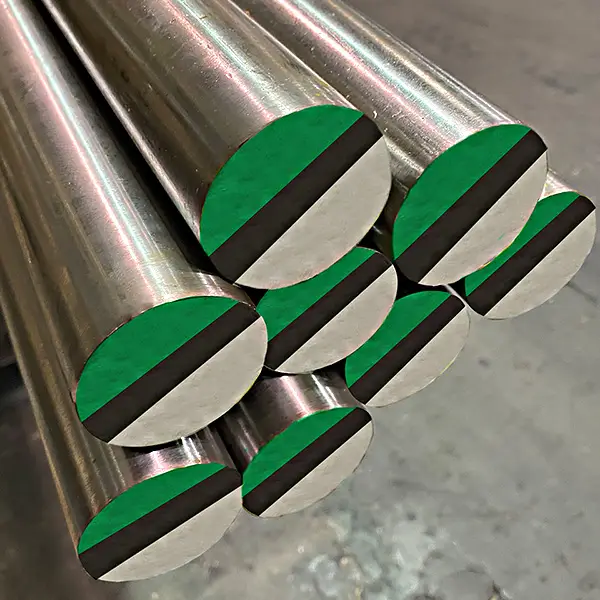

We are committed to providing one-stop service for steel pipe products to customers around the world.

42CrMo4 steel is a low alloy steel containing chromium, molybdenum, and manganese. It is widely used across numerous industries and is an excellent material choice due to its toughness, high fatigue strength, and abrasion and impact resistance. Not many grades can match the versatility and usefulness。

Chemical Properties

|

C |

Cr |

Mn |

Si |

Mo |

S |

P |

|

0.38-.43% |

0.80-1.10% |

0.75-1.0% |

0.15-0.30% |

0.15-0.25% |

0-0.040% |

0-0.035% |

Mechanical Properties

|

Properties |

Metric |

Imperial |

|

Tensile strength |

655 MPa |

95000 psi |

|

Yield strength |

415 MPa |

60200 psi |

|

Bulk modulus (typical for steel) |

140 GPa |

20300 ksi |

|

Shear modulus (typical for steel) |

80 GPa |

11600 ksi |

|

Elastic modulus |

190-210 GPa |

27557-30458 ksi |

|

Poisson’s ratio |

0.27-0.30 |

0.27-0.30 |

|

Elongation at break (in 50 mm) |

25.70% |

25.70% |

|

Hardness, Brinell |

197 |

197 |

|

Hardness, Knoop (converted from Brinell hardness) |

219 |

219 |

|

Hardness, Rockwell B (converted from Brinell hardness) |

92 |

92 |

|

Hardness, Rockwell C (converted from Brinell hardness. Value below normal HRC range, for comparison purposes only) |

13 |

13 |

|

Hardness, Vickers (converted from Brinell hardness) |

207 |

207 |

|

Machinability (based on AISI 1212 as 100 machinability) |

65 |

65 |

Heat Treatment

42CrMo4 alloy steel is heated at 845°C (1550°F) followed by quenching in oil. Before hardening, it can be normalized by heating it at 913°C (1675°F) for a long period of time, followed by air cooling.

Forging

42CrMo4 alloy steel is forged at 926 to 1205°C (1700 to 2200°F)

Hot Working

42CrMo4 alloy steel can be hot worked at 816 to 1038°C (1500 to 1900°F)

Cold Working

42CrMo4 alloy steel can be cold worked using conventional methods in the annealed condition.

Annealing

42CrMo4 alloy steel is annealed at 872°C (1600°F) followed by slowly cooling in the furnace.

Tempering

42CrMo4 alloy steel can be tempered at 205 to 649°C (400 to 1200°F) depending upon the desired hardness level. The hardness of the steel can be increased if it has a lower tempering temperature. For example, a tensile strength of 225 ksi can be achieved by tempering at 316°C (600°F), and tensile strength of 130 ksi can be achieved by tempering at 538°C (1000°F).

Hardening

42CrMo4 alloy steel can be hardened by cold working, or heating and quenching.

Machinability

42CrMo4 alloy steel has good machinability in the annealed condition.