Estamos comprometidos a brindar un servicio integral para productos de tubería de acero a clientes de todo el mundo.

AISI/SAE 4130 steel grade is a versatile alloy with good atmospheric corrosion resistance and reasonable strength up to around 315º C (600º F). It shows good overall combinations of strength, toughness and fatigue strength.

AISI 4130 alloy steel is a medium carbon, low alloy steel in ASTM A29 standard. ASTM 4140 steel is also commonly referred to as a chromoly steel, or chrome moly steel, containing nominally 0.28-0.33% Carbon, 0.8-1.1% Chromium and 0.15-0.25% Molybdenum. It is similar to 4140 steel which has a higher carbon level (0.28-0.33%), giving 4130 material improved weldability, at the expense of through thickness strength. With the proper heat treatment it is also readily machined. Annealing ASTM 4130 alloy steel offers excellent ductility. AISI 4130 steel is usually supplied as round bar commonly in the hardened and tempered condition

AISI 4130 Steel Specification and Relevant Standards

|

Country |

USA |

BS |

BS |

Japan |

|

Standard |

ASTM A29 |

EN 10250/EN10083 |

BS 970 |

JIS G4105 |

|

Grades |

4130 |

25CrMo4/1.7218 |

708A25/708M25 |

SCM430 |

ASTM 4130 Steels And Equilvalents Chemical Composition

|

Standard |

Grade |

C |

Mn |

P |

S |

Si |

Cr |

Mo |

|

ASTM A29 |

4130 |

0.28-0.33 |

0.40-0.60 |

0.035 |

0.040 |

0.15-0.35 |

0.80-1.10 |

0.15-0.25 |

|

EN10250 |

25CrMo4/ |

0.22-0.29 |

0.60-0.90 |

0.025 |

0.035 |

≦0.40 |

0.90-1.2 |

0.15-0.30 |

|

JIS G4105 |

SCM430/ |

0.28-0.33 |

0.60-0.85 |

0.030 |

0.030 |

0.15-0.35 |

0.90-1.2 |

0.15-0.30 |

AISI 4130 Steel Mechanical Properties

|

Properties |

Metric |

|

Tensile strength, ultimate |

560 MPa |

|

Tensile strength, yield |

460 MPa |

|

Modulus of elasticity |

190-210 GPa |

|

Bulk modulus (Typical for steel) |

140 GPa |

|

Shear modulus (Typical for steel) |

80 GPa |

|

Poissons ratio |

0.27-0.30 |

|

Elongation at break (in 50 mm) |

21.50% |

|

Reduction of area |

59.6 |

|

Hardness, Brinell |

217 |

|

Hardness, Knoop (Converted from Brinell hardness) |

240 |

|

Hardness, Rockwell B (Converted from Brinell hardness) |

95 |

|

Hardness, Rockwell C (Converted from Brinell hardness, value below normal HRC range, for comparison purposes only.) |

17 |

|

Hardness, Vickers (Converted from Brinell hardness) |

228 |

|

Machinability (Annealed and cold drawn. Based on 100% machinability for AISI 1212 steel.) |

70 |

Thermal Properties

|

Properties |

Metric |

|

Thermal conductivity (100°C) |

42.7 W/mK |

Smelting Option

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

Forming Option

1 Hot rolling process

2 Hot Forging: Electro-hydraulic; High-speed-hydraulic; Oil-hydraulic; Precision-forging

Heat-treatment Option

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Suface Option

1 Black Surface

2 Grounded: Bright but rough ; Not precision

3 Machining for plate: Bright and precision; Little turning scar

4 Peeled/Turned: Bright and precision; Little turning scar

5 Polished: Very Bright and precision size; Not turning scar

Other Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

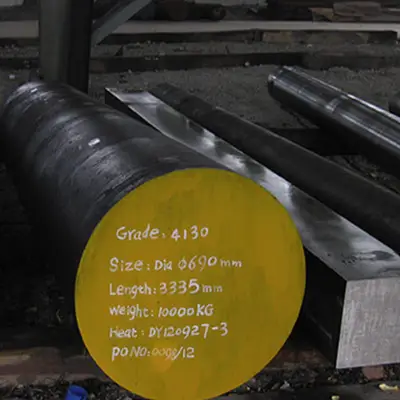

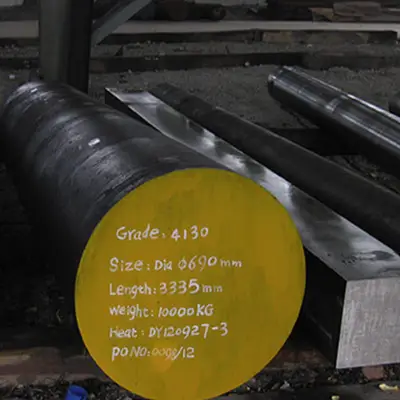

Forging of 4130 Alloy Steel

ASTM A29 Grade 4130 steel should be forged between 1230 and 950 º C (2250 and 1750 º F). The lower the finishing temperature from forging, the finer will be the grain size. If the 4130 alloy steel is forged at too low a temperature, there is a risk of the formation of a non-uniform structure in certain areas of the forged part, necessitating a normalizing treatment, prior to further heat treatment.