In the fields of oil, gas, water conservancy and construction, straight seam submerged arc welded steel pipe (LSAW) and double-sided submerged arc welded steel pipe (DSAW) are two common types of welded steel pipes. Despite the similar names, there are significant differences in their manufacturing processes, performance characteristics and application scenarios. This article will deeply analyze the core differences between the two and explore their practical application choices in different projects.

1. Definition and manufacturing process of

LSAW and DSAW

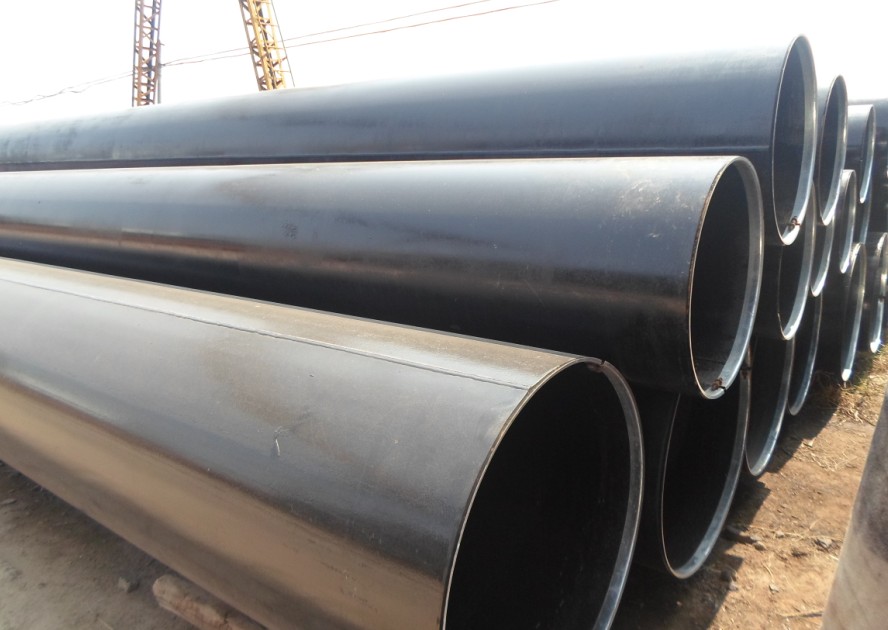

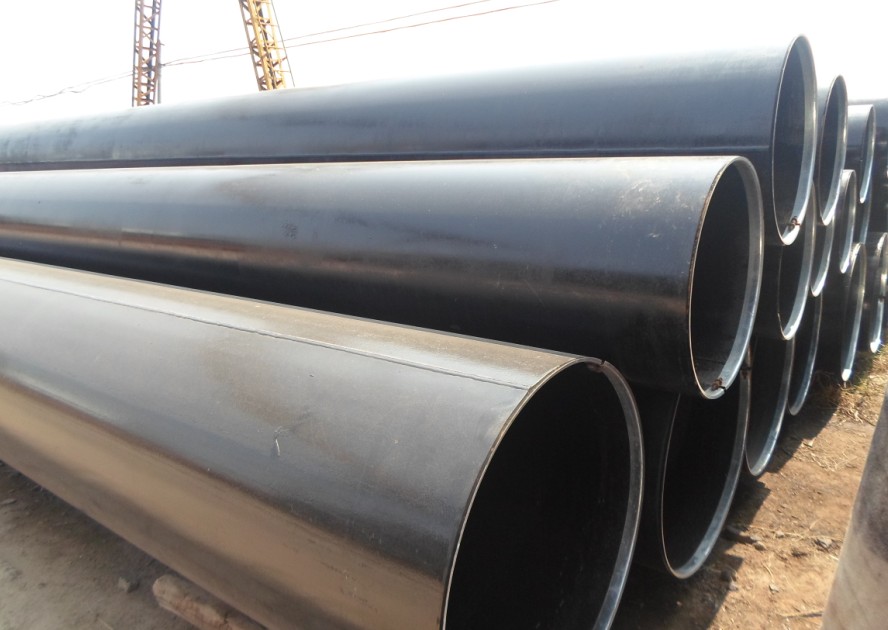

1. LSAW (Longitudinally Submerged Arc Welded Pipe)

Manufacturing process:

The steel plate is bent into a tubular shape along the length direction (longitudinally) and welded by single-sided or double-sided submerged arc welding process. According to the forming method, it can be divided into:

UOE steel pipe: The steel plate is expanded after U-shaped and O-shaped forming, with high strength and precise size.

JCOE steel pipe: It is formed by progressive stamping and is suitable for small batch production.

Features:

The weld is parallel to the axis of the steel pipe, the weld length is short, the welding quality is stable, the wall thickness is uniform, and the pressure bearing capacity is strong.

2. DSAW (Double Submerged Arc Welded Pipe)

Manufacturing process:

Usually refers to spiral submerged arc welded steel pipe (SSAW, Spiral Submerged Arc Welded Pipe), which is formed by spirally curling the steel strip and using double-sided submerged arc welding (one weld on the inside and outside).

Features:

The weld is distributed in a spiral shape, the welding length is long, the production efficiency is high, but the residual stress is high and the dimensional accuracy is slightly low.

2. Differences in core application scenarios

1. Main applications of LSAW

Long-distance oil and gas pipelines:

Applicable to high-pressure, large-diameter (usually ≥16 inches) oil and gas trunk lines, such as the West-East Gas Transmission Project.

Marine engineering:

Used for submarine pipelines and platform structure piles, which need to withstand high pressure and corrosive environments.

Special environments:

Pipelines under harsh conditions such as high cold and deep sea rely on their high toughness and brittleness resistance.

Standard reference:

Meet high standards such as API 5L and GB/T 9711.

2. Main applications of DSAW (SSAW)

Municipal engineering:

Medium and low pressure pipeline systems such as urban water supply and drainage, gas transmission, etc.

Building structure:

Used for building pile foundations and supporting structures, low cost and easy to process.

Agricultural irrigation:

Low pressure water pipeline, spiral structure flexibility to adapt to undulating terrain.