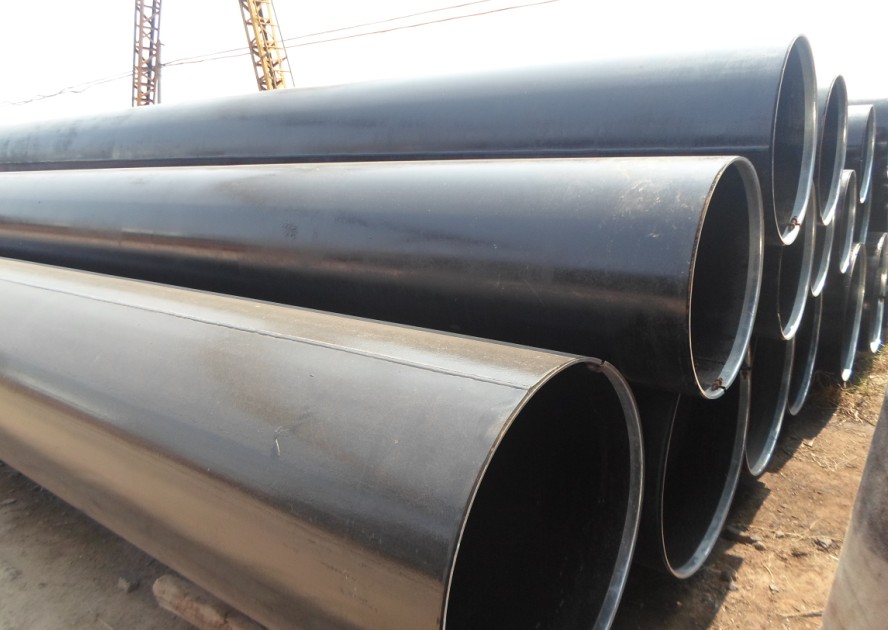

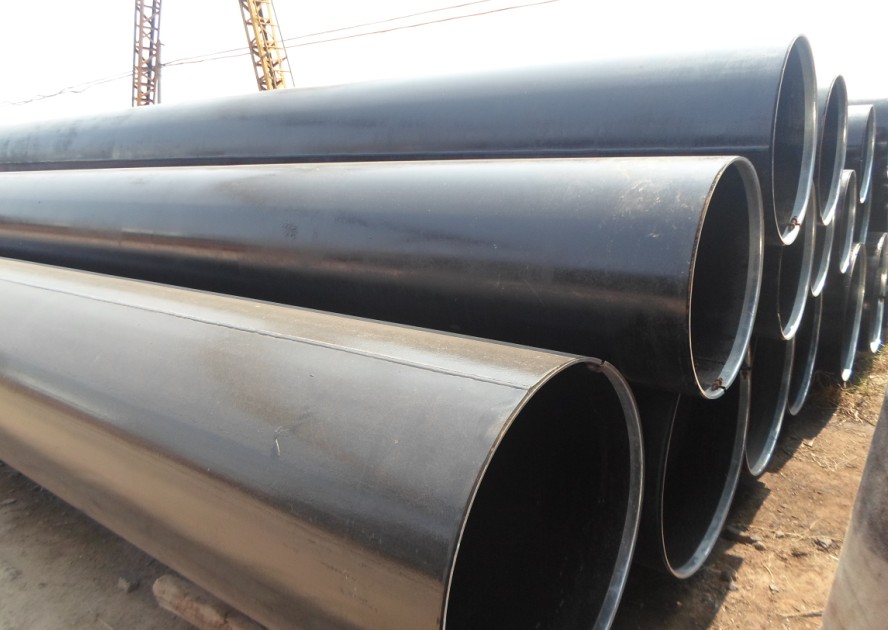

I. Hydrogen embrittlement phenomenon and industry challenges

Hydrogen embrittlement refers to the phenomenon that metal materials lose toughness and brittle fracture due to the penetration of hydrogen atoms in a hydrogen environment. It is common in oil and gas pipelines, chemical equipment and hydrogen energy equipment. With the rapid development of the global hydrogen energy industry (the green hydrogen market is expected to exceed US$300 billion in 2030), traditional steel pipes are difficult to meet the needs of high-pressure hydrogen (≥20MPa) or sulfur-containing oil and gas environments, and hydrogen embrittlement-resistant steel pipes have become a key technical bottleneck.

II. Core technical paths for hydrogen embrittlement-resistant steel pipes

1. Material design

Low-alloy high-strength steel: By reducing the carbon content (C≤0.1%) and adding alloying elements such as Cr/Mo/V, hydrogen trap sensitive sites are reduced (such as the BG110H steel grade developed by Baosteel).

Austenitic stainless steel: Nickel-based alloys such as 304L and 316L have excellent hydrogen embrittlement resistance due to their face-centered cubic structure, but the cost is relatively high (about 3-5 times that of ordinary steel pipes).

2. Microstructure regulation

Grain boundary engineering: Refine the grains through controlled rolling and controlled cooling process to reduce hydrogen diffusion channels (such as JFE's "J-HITEN" technology).

Nano precipitate phase: Introduce TiC/NbC nanoparticles to fix hydrogen atoms (such as Nippon Steel's "HTUFF" steel pipe).

3. Surface treatment and coating

Liner anticorrosion: Use aluminum/zinc coating or polymer lining (such as PTFE) to block hydrogen penetration.

Shot peening: Inhibit hydrogen-induced crack propagation through surface compressive stress layer.

4. Hydrogen compatibility test standard

NACE TM0177 (National Association of Corrosion Engineers)

ISO 11114-4 (Material compatibility in hydrogen environment)